Edgar

Service TechnicianP: 905.568.2002

F: 905.568.2024

[email protected]

Edgar

Service TechnicianP: 905.568.2002

F: 905.568.2024

[email protected]

Keith

Sales & DemonstrationsP: 905.568.2002

F: 905.568.2024

[email protected]

Halyna

Sales Support & ReceptionP: 905.568.2002

F: 905.568.2024

[email protected]

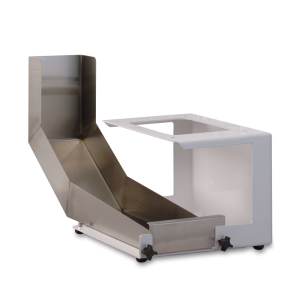

The C-series is the Sveba-Dahlen range of compact rack ovens, designed for installation in restricted spaces. A small footprint, highly effective, simple and flexible, are key characteristics of the rack ovens of the C-series.

Sutha

Accounts Payable Supervisor & LogisticsP: 905.568.2002

F: 905.568.2024

[email protected]

1 – 30 Tonne TREVIRA Silo

200 kg stainless steel hopper

We will be located at BOOTH 233 at the Bakery Showcase May 1 – 3 2016 at the International Center Hall 5. Features included an on-site test bakery with continuous demonstrations throughout the show. Find Out More

to fit with Glimek bread line

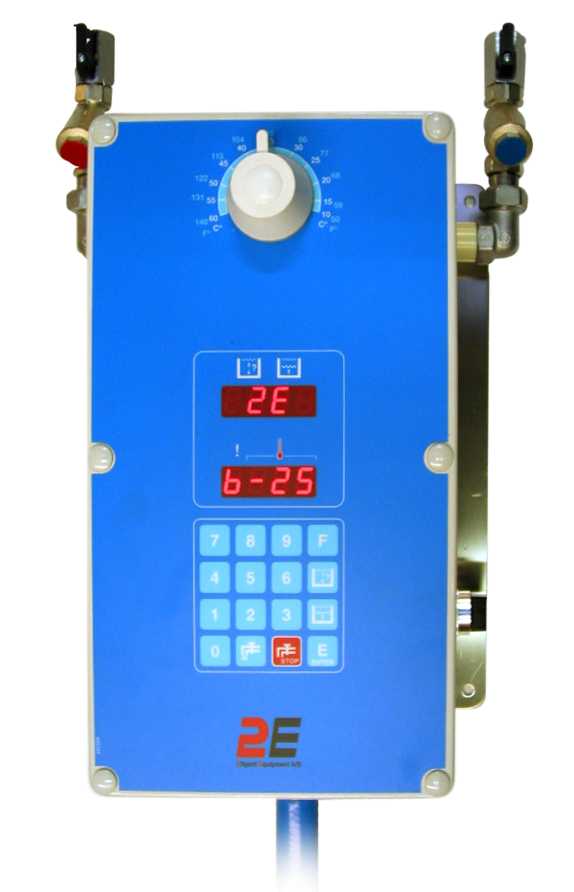

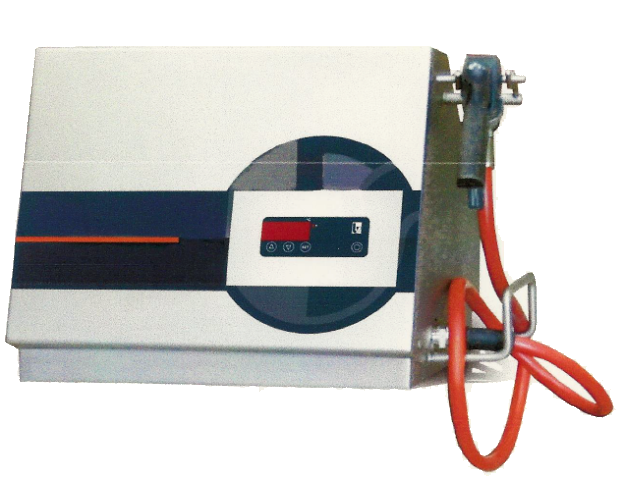

The B25 is designed for operation in bakeries requiring capacities in the area of 25 l/min (at an inlet pressure of approx. 3 bar) and an accurate temperature control.

20 liter complete with guard, beater, hook

Aluminum Standard Bun Tray, 18 x 26” x 1” rim height. The most versatile pan in the market.

Other available sizes include: 13 x 18” and 15” x 21”.

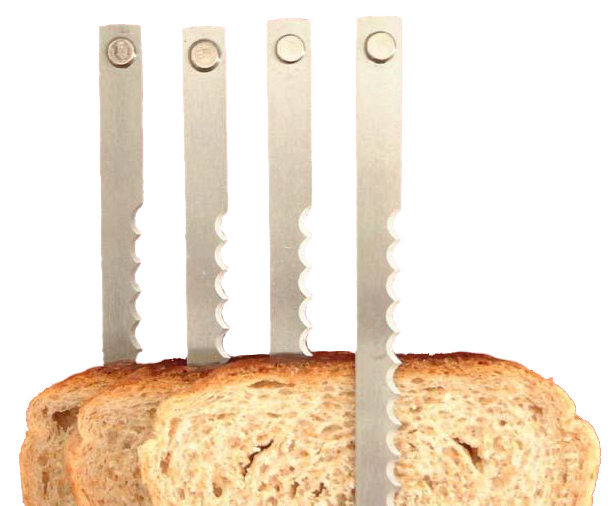

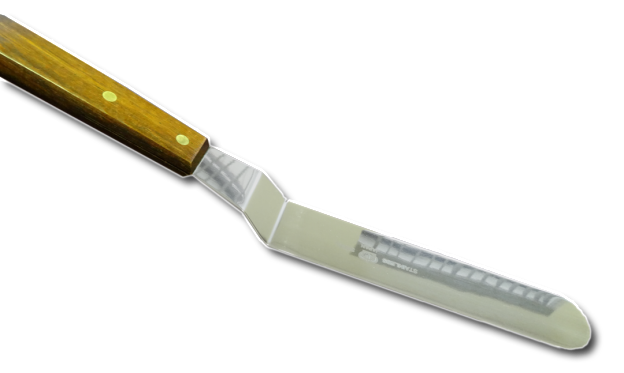

Quick Blade Changing Tool makes changing slicer blades easy and safe. Works with Oliver slicer models 709, 711, 732, 777, 797. Part No. 0797-0183-006

For pricing and information, please confirm your slicer brand and model, overall blade length (and pin center to center if applicable)

We handle a wide variety of rounding plates for Kemper, Erika Record, Rondo, Fortuna, Eberhardt, Erka, Olympia, GLIMEK, L&M, Chanmag and more. In stock both in our Mississauga and Burnaby warehouses.

Contact us today with you machine make and model and the number stamped on your existing plates. If this is not available, please contact us to receive one our easy to use Plate Identification Template.

We offer a wide variety of food approved grease and lubricants as well as high temperature chain lubricants.

We offer competitive pricing on endless and laced belts. Please call us with your machine Brand and Model to further discuss.

Indor silo series SILSYSTEM for food stuff in antistatic trevira fabric with built-in filtering roof. Silo is custom made and suited for powders of density up to 1,3 kg/liter. The modular structure in galvanized steel allows quick assembling and disassembling. CAPACITY: 1-70 Mc.

TECHNICAL DETAILS:

ACCESSORIES:

Indoor Big Bag Unloading System in painted or stainless steel, built with material suited to the storing and conveying of food stuff. Eases the emptying of Big Bags.

Modular structures in stainless steel suitable for all room solutions.

TECHNICAL DETAILS AND STANDARD EQUIPMENT:

Silos are built with materials suitable for the storing of solid food stuff. Integrated dosing groups for the managment of microingredients. Structures are modular and adaptable to all room solutions, and always allow enlargments and future changes. Ingredients loading is performed manually by discharging the bags inside the hopper or by sucking the products directly from the bag from the ground level.

PATENTED MICRODISPENSERS TRIMIX: Allow the volumetric dosing of powder products. Can be used with homogenizer-fluidizer with the most difficult products. Interchangeable between products. Hoppers are completely modular therefore the capacity increases by bsimply adding a module to the base block. Group is entirely closed to avoid pollution of the stored material and powder leaks.

| Loading cell Built in high precision tin stainless steel, with anchoring bolts, 5 meters connecting cable and flexible support. Standard (10, 25, 50, 100, 150, 250, 500, 750, 1000, 1500 Kg) and custom weight. |

|

| Antiexplosion hatch For silos and hoppers, built in stainless steel and equipped with limit switch to signal breaking. |

|

| Capacitive probe Detects maximum and minimum level, with feeding: 24 V, contact NA in exchange, screw for regulation and calibration, joints and props and 1 meter electrical cable. |

|

| Security valve Mechanic for silo, built in stainless steel AISI 304. Maximum pressure: 270 mm circa, minimum pressure: 20 mm circa. Equipped with regulation bars with sigil and protection carter in steel. |

|

| Cepatic security valve Connected to silos, allows active control of pressure in the loading from tank to silo. |

|

Filters

|

Come and see us at the IBA show in Munich, Germany in September 12 – 17, 2015.

iba has been the meeting point for experts of the baking, confectionery and snack industry since 1949. More than 1,200 exhibitors from all over the world present the industry’s latest innovations, trends and technical developments in Munich. The world’s leading trade fair for bakery, confectionery and snacks delights more than 70.000 visitors from over 160 countries.

The show dates are September 12 – 17, 2015. More information about the show can be found at their website – http://www.iba.de/en.

We’ll be doing another ‘In House Show’ at Harvest warehouse locations in Toronto and Vancouver. Stay tuned for further details and dates.

Section 1: manual infeed (rolls) or flipper device (pretzels)

Section 2: 3 lye “showers”

Section 3: automatic outfeed

3 sizes available:

| Blade length | Overall Length |

| 4-1/4″ | 8-1/4″ |

| 7-3/4″ | 13″ |

| 9-1/2″ | 14-1/2″ |

086 Semiautomatic Bag Closing System is a versatile machine that offers a wide variety of options. The machine will close bags with the all-plastic closure and closure-labels. The 086 is also available with a printer that will print code information on the closure and/or closure-label. Featured is a power breakoff and closure advance mechanism. The simple design of the 086 is portable, jam-proof and compact, and can close bagged packages up to 30 bags per minute.

18×26” poplar wood

Available lengths:

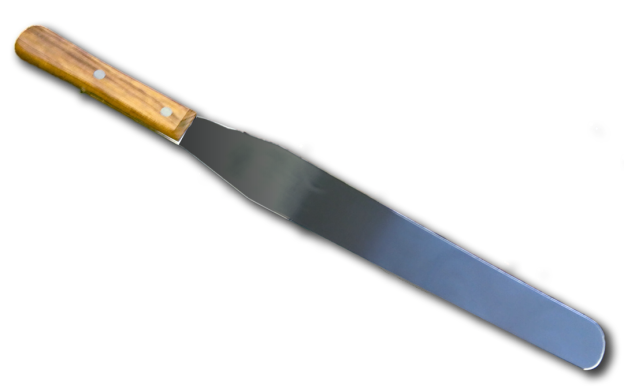

| Blade length | Overall Length |

| 4″ | 8″ |

| 5″ | 9″ |

| 8″ | 12-3/4″ |

| 10″ | 15″ |

| 12″ | 17″ |

Widths available:

12”/14”/16”/18”/20”/22”

LINEN

23-1/2” width (60cm)

Made of 100% natural linen fibers with no chemical color or treatments used, linen is the best material for proofing breads. Linen is very durable, but flexible and light, which allows the folds needed separating the shape of dough. Shaped loaves of bread are placed in between the folds of linen to help the bread maintain its shape during proofing, reduce the amount of space needed in between the loaves, and prevent the loaves from proofing into each other. Linen will absorb the excess moisture of the dough and minimize stickiness during proofing or overnight retarding but will not dry it out, giving a nice thin crust. Maintenance: scrape or brush after every usage, and then hang to dry before using again.

SOLD BY THE METER ( it is recommended to hem the edges to prevent fraying)

The MO300 is available with a wide variety of options to suit the customers needs.

Versatility and Affordability – The Merand Divider/Shaper combines several machine functions into one. Can be used as a Press, Hydraulic Divider, Divider Shaper for most cut products as well as a Baguette Divider/Shaper option. Call for further information

Hydraulic Divider Options

Product Specifications:

| Mode | # of pieces | total tank capacity* |

|---|---|---|

| Hydraulic Mode: | 20 division | up to 20 kg dough |

| Baguette Mode: | 8 or 10 division | up to 3.5 kg dough |

| Div-X Model: | see grid chart | up to 7 kg dough |

*tank capacity is dependent on dough type/density and are guidelines only. Note in Div X mode the variety of grids will determine your quantity of dough pieces and total dough capacity.

Features

Machine to roll and to shape dough balls with weight from 50 grams (1.76 oz) to 1 450 grams (3.19 lb). The Production rate is up to 1 800 parts per hour depending on the dough ball weight.

Marika

Sales & AccountingP: 604.294.6650

F: 604.294.6693

[email protected]

The Flexible bread line is very user friendly and flexible with a high capacity and efficiency.

It handles a wide variety of dough types and sizes which makes the bread line very flexible and efficient. The Flexible bread line consists of the following freestanding machines:

Conrad

Sales DirectorP: 905.568.2002

F: 905.568.2024

[email protected]

Cornel

Technical SupportP: 905.568.2002

F: 905.568.2024

[email protected]

Dave

Parts & Service Co-ordinatorP: 905.568.2002

F: 905.568.2024

[email protected]

Brushes with Natural Bristle

Bristle length approximately 1-1/2″ (40mm); Overall Length 9-1/2″ (240mm)

Three sizes available:

| 1-1/2″ wide (40mm) |

| 2-1/2″ wide (60mm) |

| 3″ wide (75mm) |

Available Sizes:

| Capacity | Size |

| 5 oz. | 4-3/4″ x 2-1/2″ |

| 12 oz. | 6-1/4″ x 3-1/4″ |

| 24 oz. | 8″ x 4″ |

| 38-1/2 oz. | 9″ x 4-3/4″ |

| 57-1/2 oz. | 10-1/4″ x 5-1/2″ |

| 84-1/2 oz. | 12″ x 6-1/4″ |

The Straight Dough Line is specially made for producing bread without need for an intermediate proving time. Its a very compact dough line with capacity of up to 1800 pieces per hour and a with a weight range of 120 up to 1600 grams.

Joanna

Accounts Receivable SupervisorP: 905.568.2002

F: 905.568.2024

[email protected]

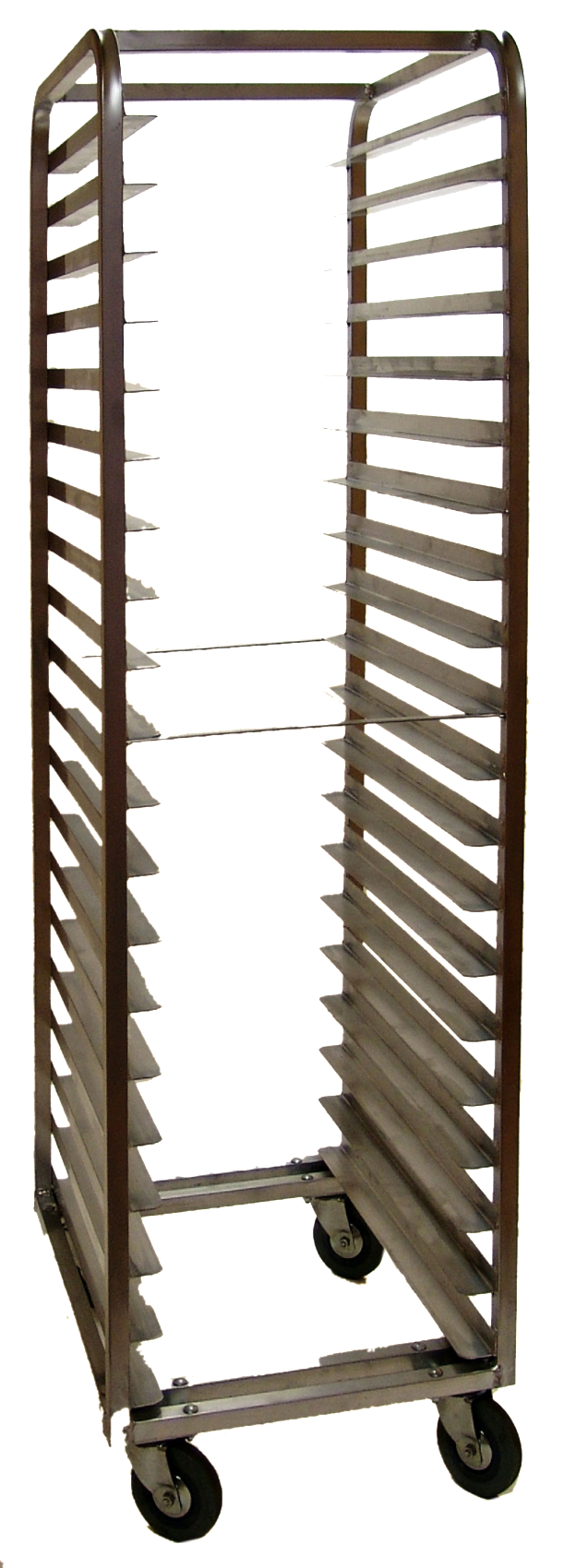

Single WELDED Racks

| Item # | # of Slides | Slide Spacing |

| 61810-REG | 10 | 6” |

| 61812-REG | 12 | 5” |

| 61816-REG | 16 | 3-3/4” |

| 61818-REG | 18 | 3-1/3” |

| 61820-REG | 20 | 3” |

| 61824-REG | 24 | 2-1/2” |

| 61830-REG | 30 | 2” |

| 61840-REG | 40 | 1-1/2” |

Single WELDED Racks

| Item # | # of Slides | Slide Spacing |

| 61810-HTS | 10 | 6” |

| 61812-HTS | 12 | 5” |

| 61816-HTS | 16 | 3-3/4” |

| 61818-HTS | 18 | 3-1/3” |

| 61820-HTS | 20 | 3” |

| 61824-HTS | 24 | 2-1/2” |

| 61830-HTS | 30 | 2” |

| 61840-HTS | 40 | 1-1/2” |

All racks are 20-1/4” outside width x 26” depth by 69” height

| Item# | Pan Size | #of slides | Slide spacing |

| 5181 | 18×26” | 10 | 6” |

| 51812 | 18×26” | 12 | 5” |

| 5182 | 18×26” | 20 | 3” |

| 51824 | 18×26” | 24 | 2-1/2” |

| 5184 | 18×26” | 40 | 1-1/2” |

All welded construction with 4 heavy duty all swivel casters. Designed to fit into any spot where space is at a premium.

All-welded construction with 4 heavy duty all-swivel casters so dolly can roll in any direction. Designed to hold 100 pc. 18×26” bun pans.

Vinyl clear rack cover are perfect for keeping food fresh and free from contaminates. Heavy duty zippers are used. Fits standard single rack.

The well established, heavy duty quality!

| Sizes | Length (cm) |

| 0 | 25 |

| 1 | 28 |

| 2 | 34 |

| 3 | 40 |

| 4 | 46 |

| 5 | 50 |

| 6 | 55 |

| 7 | 60 |

| 8 | 65 |

| 9 | 70 |

| 10 | 75 |

Short/Oval:

| Weight | Dimension |

| 500 gram | 220 x 130mm or 200 x 140mm |

| 750 gram | 240 x 125mm |

| 1000 gram | 320 x 130mm |

| 1250 gram | 360 x 130mm |

| 1500 gram | 370 x 140mm |

Heavy duty zippers are used. Standard freezer rack cover for 18” x26” single pan rack.

(Commercial Brand)

Long/Narrow

| Weight | Dimension |

| 750 gram | 270x120mm |

| 1000gram | 360 x 120mm |

| 1250 gram | 380x130mm |

| 1500 gram | 410 x 130mm |

A step by step elevator for transporting dough pieces from the rounder into the moulder.

| 2″ Round Layer Cake Pan | 3″ Round Layer Cake Pan | ||

|---|---|---|---|

| Item# | Description | Item# | Description |

| 204 | 4″ x 2″ | 304 | 4″ x 3″ |

| 205 | 5″ x 2″ | 305 | 5″ x 3″ |

| 206 | 6″ x 2″ | 306 | 6″ x 3″ |

| 207 | 7″ x 2″ | 307 | 7″ x 3″ |

| 208 | 8″ x 2″ | 308 | 8″ x 3″ |

| 209 | 9″ x 2″ | 309 | 9″ x 3″ |

| 210 | 10″ x 2″ | 310 | 10″ x 3″ |

| 211 | 11″ x 2″ | 311 | 11″ x 3″ |

| 212 | 12″ x 2″ | 312 | 12″ x 3″ |

| 214 | 14″ x 2″ | 314 | 14″ x 3″ |

| 216 | 16″ x 2″ | 316 | 16″ x 3″ |

| 218 | 18″ x 2″ | 318 | 18″ x 3″ |

| Weight | Dimension |

| 500gram | 190mm diameter |

| 750 gram | 200mm diameter |

| 1000 gram | 220mm diameter |

| 1250 gram | 230mm diameter |

Short/Oval:

| Weight | Dimension |

| 500 gram | 240 x 145 x 85mm |

| 750 gram | 270 x 145 x 85mm |

Elasticized cotton liners available!