Koenig

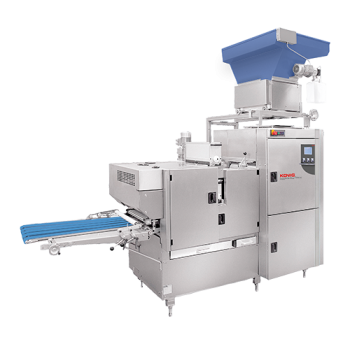

KOENIG Artisan SFC

- wide feeding belt for convenient dough feeding

- dough belt duster with large storage container and controllable drive for even dusting of the dough belt

- touch panel with pictograms for language-independent operation

- quick and easy adjustment of the machine by means of pre-installed standard programs

- max. 50 programs can be stored

- guillotine and stamping station for a maximum product variety

- dough sheet calibration system by means of innovative calibration ledges

- optionally available with dampening and seeding unit

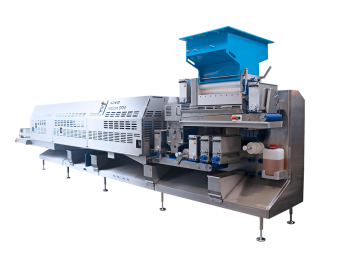

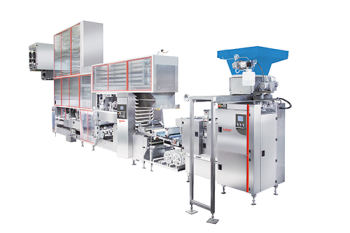

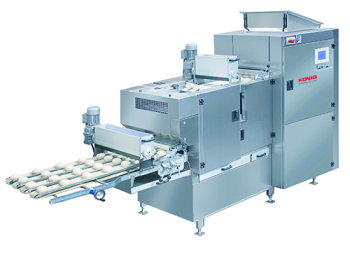

KOENIG ARTISAN SFM EC

The dough sheeting line for large and fine-pore doughs in Easy Clean Design

Performance features:

- for easy cleaning, maintenance and access to all modules, Koenig has applied the “Easy Clean” Design

- dough throughput of 400 to 1,200 kg per hour for rolls and 400 to 1,500 kg per hour for breads

- performance with angular rolls: 16,200 pieces/hour at 6-row operation (45 strokes/min.)

- performance with rounded rolls: 11,800 pieces/hour at 6-row operation (33 strokes/min.)

- absolutely gentle processing of fine- and large-pore doughs due to multiple forming rollers, adjustable for individual dough yields and bowl resting time

- new kind of dough sheet forming for gentle dough handling:

- preformer with 3-roll satellite, counter-roller and scraper for gentle preforming of the dough sheet

- a dough sheet former ensures a homogeneous dough sheet, reduction of machine length and thus reduced footprint

- for an even dough sheet and improved weight accuracy, especially for doughs with longer bowl resting time

- systems often have residual dough of up to 15%

- modular system: Modules such as forming station, seeding stations, proofer etc. available and can be retrofitted at any time

- integrated weighing system for weight-accurate production

- exchangeable cutting rollers for different dough sheet rows

- intuitive control by PLC control with 14 inch touch panel with pictograms and 99 storable programs

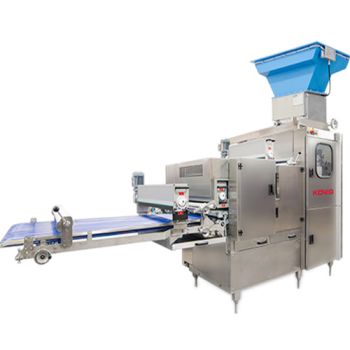

Basic Rex

- gentle operation according to the Rex principle

- 6-, 5- and 4-row machine versions

- easy change of row number possible

- capacity of machine continually adjustable from 12 to max. 25 strokes per minute

- simple operation via handwheels

- simple dough supply via chute hopper with safety light-grid

- optionally available with spreading finger belt or discharge belt

- Stainless steel design

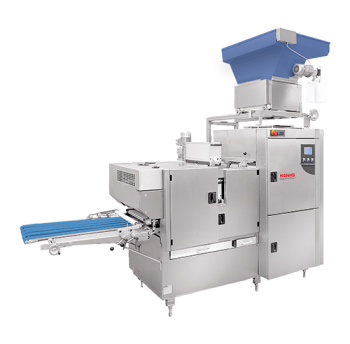

Classic Rex

- the machine for the most stringent hygiene demands

- gentle dough processing according to the tried-and-tested Rex principle

- 6-, 5- and 4-row operation

- easy change of row numbers

- fully automated machine operation by means of servomotors optionally available

- capacity of machine continually adjustable from 12 to max. 25 strokes per minute

- standard version with large shaft hopper and safety light-grid

- optionally available with roller hopper for mounting a large dough hopper

- with spreading finger belt or discharge belt

- stainless steel design

KOENIG Rex Futura Multi

- weight range of 17 to 230g (up to 600g for only divided products) adjustable with touch panel

- maximum hourly capacity of up to 9000 pieces at 6 row operation (corresponding to 25 lifts/min.)

- optimum rounding result for varying doughs through exchangeable rounding plates and electrically adjustable rounding eccentric

- easy cleaning through collapsible roller hopper, removable hopper duster unit and removable rounding plates and dividing ledges

- large operating doors for easy access for cleaning and maintenance

- operation by PLC control and touch panel

- possibility to install special pistons , e.g. so-called Rustika pistons, for the production of square, rustic-style rolls

- optimal vibration damping during operation by means of solid cast side plates

- easy dough supply through roller feeding hopper with a dough capacity of 28 kg

- integrated shelf space for divider ledges and slider blocks

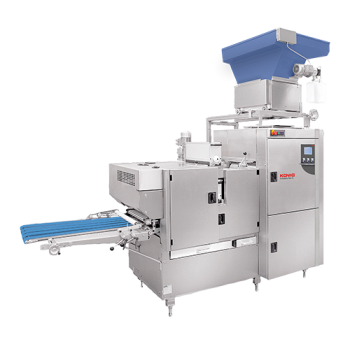

Classic Rex Futura

- extended weight range through enlarged dividing drum

- gentle dough processing according to the tried-and-tested Rex principle

- the machine for the most stringent hygiene demands

- 6-, 5- and 4-row operation

- easy change of row numbers

- fully automated machine operation by means of servomotors optionally available

- capacity of machine continually adjustable from 12 to max. 25 strokes per minute

- standard version with large shaft hopper and safety light-grid

- optionally available with roller hopper for mounting a large dough hopper

- with spreading finger belt or discharge belt

- stainless steel design

Classic Rex Plus

- gentle dough processing according to the tried-and-tested Rex principle

- the machine for the most stringent hygiene demands

- 3- and 4-row operation

- easy change of row numbers

- capacity of machine continually adjustable from 12 to max. 20 strokes per minute

- simple dough supply via roller hopper with safety light-grid

- machine operation via touch panel

- stainless steel design

Grande Rex

- 3- or 4-row operation

- max. hourly capacity: approx. 2800 pieces with max. 12 strokes/min

- simple dough supply via shaft hopper with safety light-grid

- simple operation via handwheels

- plastic drum free of oil

- stainless steel design

Grande Rex Futura

- 3- or 4-row operation

- max. hourly capacity: approx. 2800 pieces with 12 strokes/min

- simple dough supply via shaft hopper with safety light-grid

- simple operation via handwheels

- plastic drum free of oil

- stainless steel design

Mini Rex Multi

Weight range from 8 to 330 g (up to 140 g rounded) — depending on dough

- max. hourly capacity in the 1-, 2-, 3-row or 4-row version: 1200, 2400, 3600 or 4800 pieces

- easy and safe change of the dividing drum ledges for different weight ranges and changes of number of rows

- roller hopper for approx. 15 kg dough capacity

- all components that come in contact with the dough can be removed from the machine for easy cleaning

- stainless steel design

- Easy control with micro controller via touch panel

- all mechanical settings can be stored in the program

- direct access to stored programs

- robust industrial version with LED display

- clearly legible, 3-digit digital display

- Slot for SD memory card for backup and easy software update

KOENIG Roto Passat

Especially easy to maintain due to

- the door with easily exchangeable all-round sealing, no tools required

- “door-in-door” system for easy cleaning

- impact protection, inside and outside

- optimal cooling of the control elements

- quickly removable floor rotating table for easy cleaning

- light and separated maintenance lid on the front section

Hygienic finish due to

- the exclusive use of smooth surfaces made of stainless steel

- easily removable ramp, no tools required

- stainless steel labyrinth under the floor rotating table protecting the oven floor against soiling

- removable floor cover sheets – so the oven floor is quickly accessible and easy to clean

- efficient extractor fan shaft

Increased energy efficiency due to

- the new cloud device that makes for an optimal use of the quantity of water added

- “Energy+ High End” heater – setting a new benchmark for energy efficiency in rack ovens

KOENIG Passat OH

- the rack oven with standing baking trolley for bread and rolls

- reciprocal flow of hot-air above products

- design combining attractive appearance with easy operation

- touch screen operation enables easy input of required values and rapid effect on the baking process

- long working life and value

- stainless steel design

KOENIG PU Integral

- baking surface up to 140 sqm possible

- baking plate sizes: 2,500 x 1,300 mm or 3,000 x 1,300 mm

- several independent baking zones for the regulation of temperature, air volume and humidity enable optimized product quality for all baked goods

- innovative sealing system for the individual baking zones

- the production of part-baked products with very short baking times is realized with two independently working loading trolleys

- increased energy efficiency thanks to thermo oil heat exchanger

- the compact construction requires minimal space and guarantees minimal heat losses

- optionally available also without independent baking zones and with heater for oil or gas burner

Mini Rex Futura

- capacity of up to 4000 pieces/hour, set at 33 strokes/min.

- extended weight range through the combination of 2 dividing stamp sizes

- optimum rounding results via continually adjustable rounding eccentric

- roller hopper with approx. 15 kg dough capacity

- 2-row operation

- industrial PLC control with quick access keys

- also available with special stamps

- quick access keys

KOENIG Industry Rex I

- automatic dough dividing and rounding machine according to the Rex principle

- max. hourly capacity of approx. 24,000 pieces with max. 50 strokes/min in the 8-row version

- simple dough supply via roller hopper with safety light-grid

- industrial PLC control

- stainless steel design

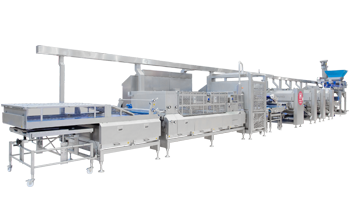

KOENIG ECO 4000

4000

- maximum hourly capacity of 5,100 pieces with 5-row operation

- entire line can be moved on wheels, with movable head machine

- top processing quality through the use of premium stainless steel materials

- space-saving compact design

- setting adjusted to Euro standard baking tray sizes

- optional additional device for optional setting face up or face down

- use of a wide range of individual stamping tools possible through carrier plate insert

- also available with prover for approx. 10 or 20 minutes final proving time

- final prover disconnectable on request

- optionally with cross conveyance for pre-proven dough pieces such as convoluted goods

- optionally available with baking tray manipulator Servomat

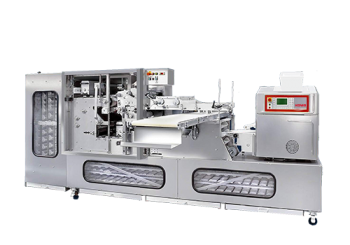

KOENIG Certo Pan M

- dough throughput of up to 600 kg per hour

- maximum hourly capacity of 7,500 pieces (square rolls) or 6,000 pieces (rounded rolls) when working with 5 rows

- infeed of dough via integrated box lifting unit

- endless dough sheet production by the use of a rotating disc hopper and an oscillating cutting knife

- exchangeable cutting rollers for varying numbers of rows for the dough sheet

- usable dough sheet width approx. 240 mm

- even dough pieces with high weight accuracy through endless dough sheet

- optimal cleaning on account of large maintenance doors and swiveling disc hopper

- easy operation with PLC control and touch panel with pictograms

KOENIG Industry Rex II

- automatic dough dividing and rounding machine according to the Rex principle

- max. hourly capacity of approx. 30,000 pieces with 50 strokes/min in the 10-row version

- simple dough supply via roller hopper with safety light-grid

- industrial PLC control

- stainless steel design

KOENIG Eco Twin

- great price-performance ratio

- 800 mm version: 6-/5-row operation

- 600 mm version: 5-/4-row operation

- pre-prover line of a length of only 3,480 mm

- with additional direct set-down as standard

- quickly changeable stamping tools and cutting tools

- made of stainless steel – of stable value over many years

- entire line sits on an underframe with wheels

- for Eco Twin 600, also available with final prover for 20 minutes final proving time

- variable set-down by means of retracting unit on to common proving trays / baking trays

- retracting lengths and steps of the dough pieces when set down are continually adjustable

- with direct set-down as standard

- available with additional Wachauer rounding station as special design

- optionally with cross conveyance for pre-proven dough pieces such as convoluted goods

- optionally available with baking tray manipulator Servomat

KOENIG Industry Rex III

- automatic dough dividing and rounding machine according to the Rex principle

- max. hourly capacity of approx. 42,000 pieces with 50 strokes/min in the 14-row version

- simple dough supply via roller hopper with safety light-grid

- stainless steel design

KOENIG Combiline

- hourly capacity up to 9,000 pieces.

- modular system

- easily expandable at a later stage

- modular design for the entire line

- also available with direct transfer for the setting of raw dough pieces

- variable setting onto baking trays or proving trays

- available with a working width of 600 or 800 mm

- top processing quality through the use of premium stainless steel materials

- hygienic design for easy cleaning and maintenance

- optionally with cross conveyance for pre-proven dough pieces such as convoluted goods

- optionally available with baking tray manipulator Servomat

KOENIG Mini Rex – DR-RR400

DR-RR400

- compact design

- fully automated dividing and rounding of wheat doughs and rye- -wheat doughs with a maximum rye percentage of 40%

- can be combined with Mini Rex Futura as well as Mini Rex Multi

- excellent results with the production of round, long-rolled, long-rolled and folded as well as flattened goods

- maximum hourly capacity of up to 4,000 pieces.

- weight ranges Mini Rex Futura / Mini Rex Multi

- height-adjustable calibrating head, folding net belts, lower belt and upper belt for ergonomic working with the following functions: transporting, long rolling, pressing flat

- teflonized collecting drawer for manual product removal

- also available with seeder

- quick and easy cleaning on account of plug-in elements

- stainless steel design

KOENIG Ceres 2.2

2.2

- for all doughs with a dough yield between 162 and 182

- for all doughs ranging from 100% wheat to 100% rye

- for all doughs with pre-dough and long bowl resting time

- minimal cleaning efforts on account of easy access to the parts to be cleaned, extra cleaning menu, movable dough belt sensors, removable transfer disc and belts of synthetic material

- dough divider with patented gravitation dough sheet technique

- hopper with a volume of 300 liters and 900 mm height for more bowl proving – no pre-portioning hopper required

- sensor-controlled weighing device

- designed for one-man operation

- designed in accordance with the latest applicable hygiene regulations

- electric lifting and lowering of the hopper

- shortest possible set-up times when changing dough sorts

- Siemens-S7 PLC control with touch panel

- bowl hoist with standard scraping device can be combined directly

KOENIG Industry Rex Futura

- automatic dough dividing and rounding machine according to the Rex principle

- different chamber sizes with enlarged dividing drum

- max. hourly capacity of approx. 14,400 pieces with 40 strokes/min in the 6-row version

- simple dough supply via roller hopper with safety light-grid

- industrial PLC control

- stainless steel design

KOENIG Spiral Mixer

- stable construction for demanding doughs

- dough capacity: 160 and 240 kg

- with two speeds for mixing tools and dough bowl as standard

- short mixing times with minimum dough warming

- head can be lifted and lowered hydraulically

- dough bowl removable

- hydraulic dough bowl locking

- standard version with stainless steel execution and stainless steel foot plate

- optionally available with stainless steel base frame

KOENIG KGV Combi 2000

2000

- maximum hourly capacity up to 18,000 pieces.

- 800 mm working width for top performance

- on request, available with direct transfer for the setting down of raw dough pieces

- ergonomic design

- convenient manual operation

- easy cleaning because all parts in touch with dough are optimally accessible

- optionally available with dampening/seeding and final prover

KOENIG Combiline Compact

- compact and stable frame design

- the tried-and-tested dough dividing and rounding machines Basic Rex, Classic Rex and Classic Rex Futura as head machines guarantee a truly royal roll line

- the tried-and-tested dough dividing and rounding machines Basic Rex, Classic Rex and Classic Rex Futura as head machines guarantee a truly royal roll line

- climate control with heating and dampening, highly efficient sterilisation facility for empty swings

- adjustable capacity of 15-25 strokes / min.

- ergonomic height for tray removal

- direct setting from head machine to setting unit possible

- integrated long rolling station for the production of cut rolls or long rolls

- retracting unit optionally equipped with extendible drawer for making work easier

- optionally with cross conveyance for pre-proven dough pieces such as convoluted goods

- optionally available with baking tray manipulator Servomat

KOENIG Mini Rex – G2000

G2000

- compact pre-prover with Mini Rex Futura or Mini Rex Multi as head machine

- max. hourly capacity with prover operation: 2,000-2,500 pieces, continually adjustable /

- for greater capacity without prover operation, Mini Rex Futura or Multi movable: 1,800-4,000 pieces, continually adjustable /

- weight ranges Mini Rex Futura / Mini Rex Multi

- one-row discharge belt for convenient manual removal

- prover with 100 useable cup swings, for a max. weight of each dough piece: 75 g

- proving time approx. 6 min., with a capacity of 2,000 pieces/hour

- stamping device with easily changeable stamping tools

- integrated folding/long rolling unit (e.g. for the production of Berlin rolls)

Industry Rex AW

- 6-, 8- or 10-row dough dividing and rounding machine in the weight range of 22-160 g

- dividing and rounding system developed from scratch

- continually adjustable, even slide pressure for greatest weight accuracy for different doughs

- max. hourly capacity: approx. 30,000 pieces with 50 strokes/min in the 10-row version

- change of the weight range through manually exchangeable dividing ledges and piston tools according to the Multi system

- exact dividing process through “stop and go” operation and specially shaped pre-chamber

- inner rounding drum with automatically adjustable rounding eccentric

- transfer belts between dividing drum and rounding drum can be folded up on both sides for easy cleaning

- drive of the transfer belts through cardan joint drive drums for maximum protection of the belt

- enlarged rounding drum for longer and thus more intense rounding of all doughs

- discharge spreading finger belt with cardan joint drive to avoid belt slippage

- main drives are encapsulated and completely separated from the dough area

- easy maintenance through large, removable maintenance doors

- ground clearance of 300 mm throughout for easy cleaning under the machine

- generous integrated shelves for machine accessories

KOENIG Twin Twist Mixer

- top-class industrial mixer

- stable construction for demanding doughs

- standard version with two speeds for mixing tools and dough bowl

- intense mixing with simultaneous gentle processing of fruit doughs, for example

- head can be lifted and lowered hydraulically

- dough bowl removable

- hydraulic dough bowl locking

- standard version with stainless steel execution and stainless-steel foot plate

- optionally available with stainless steel base frame and hygienic “H” build type (can be sprayed clean with water – call for further details)

KOENIG Combiline Compact EC – Easy Clean

The modular roll line with a capacity of 33 strokes/min in Easy Clean Design

The Combiline plus EC is a modular line which fits to the requirements of your bakery. By means of your special conditions, market requirements and investment spending, you define the configuration of the line. And Koenig builds it in the way you need it. In case you will need an additional level of automation later on, the line can be easily expanded without major engineering work and with minimal disruption to your production. The Easy Clean Design offers easier cleaning, maintenance and access to all modules.

Performance features:

- max. hourly capacity of 11,880 pieces at 6-row operation and adjusted 33 strokes/min

- available in working widths of 600 or 800 mm

- with pre-proofer „plus“ with 320 usable swings

- capacity adjustable between 18 and 33 strokes/min

- climate with heating and wetting, highly effective sterilisation unit for empty swings

- with a transfer belt after the stamping station, the setting of dough pieces is even more gentle and exact

- retracting unit accessible from three sides with tray support at ergonomic height

- direct transfer from head machine to setting unit possible to convey products with high single dough piece weight to the setting unit

- optional with cross conveyance for feeding a convoluting machine

- integrated longroller unit for the production of cut rolls as option

- an entirely new user interface simplifies operation for daily production but also for changes in programs and service activities

KOENIG INDUSTRY REX COMPACT AW

COMPACT AW

The Industry Rex Compact AW offers an ideal balance between weight accuracy and gentle dough processing. The variable separation of the dividing pistons and rows of this dough dividing and rounding machine allows to cover a weight range from 25 to 350g in only one machine – and nevertheless in compact design. To achieve this, the proven „Multi“ principle with easily exchangeable dividing ledges has been applied to this machine.

Performance features:

- the automatic dough dividing and rounding machine can operate in up to 10 rows

- high weight range of 28-350g with only one machine by means of variable separation of dividing pistons and rows

- hourly capacity of up to 30,000 pieces at 50 strokes/min

- proven Koenig pre-portioning unit

- the continuously adjustable, absolutely even pusher pressure ensures highest weight accuracy for various dough types and consistencies manually changeable dividing ledges and dividing pistons for changing the weight range according to the system Multi

- inner rounding drum with automatically adjustable rounding eccentric

- swiveling dividing drum for compact design

- discharge spreading finger belt adjustable to separations/rows

- rounding unit for gentle rounding process guarantees optimum product quality

- easy operation with touch display

Cleaning and Maintenance:

- tool-free exchangeable dividing ledges including dividing pistons

- easy cleaning with stainless steel surfaces

- large, removable maintenance doors

- drives completely separated from the dough area

- entirely removable rounding belt and rounding drum

KOENIG KGV I-VI – Program

- monoline for top hourly capacity or multifunctional line for the greatest possible product diversity

- hourly capacity up to 36,000 pieces.

- modular system for the configuration of the line according to your needs

- multiple rounds of cutting, seeding, lye application, etc. are possible

- final prover with insulation cladding and controlled climate available

- equipment with swing cleaning, vacuuming and infra-red sterilisation station is possible

- available with modem connection for remote maintenance

KOENIG KKM

- roll line for great product diversity

- hourly capacity of up to 7,500 pieces 5-/4-/3-row operation

- available with Classic Rex or Industrie Rex

- in compact modular design

- direct transfer for the setting of raw dough pieces possible

- essential components of the line, e.g. final prover, dampening, seeding, convolution station and cutting station can be easily added later, depending on the line configuration

- 3-time reversible cup for diversified product range

- premium quality for cut rolls through integrated pre-prover with long-rolling station

- optional final rounding device for second rounding sequence for the production of premium rustic-style rolls (e.g. Wachauer)

- optionally available with baking tray manipulator Servomat

KOENIG Mini Rex – GS2000

GS2000

- compact pre-prover with Mini Rex Futura or Multi as head machine

- available in K or SL version

- max. hourly capacity with prover operation: 2,000-2,500 pieces, continually adjustable /

- for greater capacity without prover operation, Mini Rex Futura or Multi movable: 1,800-4,000 pieces, continually adjustable /

- weight ranges Mini Rex Futura / Mini Rex Multi

- prover with 145 useable swings (K version with cup swings, SL version with continuous swings), max. weight of each dough piece: approx. 100g

- optionally available also with 170 or 220 useable swings

- proving time approx. 8 min., with 145 swings and a capacity of 2,000 pieces/hour

- stamping device with easily changeable stamping tools

- integrated forming station with pre-pressure roller, drag belt, lower and upper belt with continually adjustable speed for 2-row operation, cross separation max.180 mm

- one-row discharge belt for convenient manual removal

KOENIG Menes 1

1.0

- dough throughput from 500 of up to 5,000 kg per hour

- available in working widths 800/1,000/1,200 and 1,600mm

- extreme range of dough yields processable: from 140 to 190 gr.

- dough sheet thickness of 1 mm – 50mm

- “Twin Sat” double satellite head for the most gentle dough processing

- stainless steel design

- picture-oriented and simple control of the system

KOENIG Industry Rex Plus

- automatic dough dividing and rounding machine according to the Rex principle

- max. hourly capacity: approx. 8,400 pieces with 35 strokes/min in the 4-row version

- simple dough supply via roller hopper with safety light-grid

- industrial PLC control

- stainless steel design

KOENIG Herkules Bowl Hoist

- lifting power up to max. 1000 kg.

- tipping height adjustable in steps from approx. 50 mm to max. 3300 mm

- clamp for third-party bowls available optionally

- optionally in right-hand or left-hand version

- transversely movable (special version)

- also available for low tipping heights

- basic frame available in stainless steel

KOENIG KGV PLUS

Uniquely high performance of 100 strokes/min for a great variety of rolls

Performance features:

- the new type of industrial bread roll line for different products, such as hamburgers, hot dogs, milk rolls, donuts, brioche buns, etc.

- for a maximum output of 72,000 pieces/hour in 12-row execution

- high product quality and preservation of the dough structure, compared to extruder solutions

- easy processing of doughs with a developed dough structure or heterogeneous doughs with ingredients such as raisins or nuts

- the heart of the system is the T-Rex AW, a completely new dough dividing and rounding machine with a capacity of 100 strokes/min. for different dough consistencies and high weight accuracy

- the T-Rex AW offers a wide weight range of 25 to 70g

- a proofer ensures gentle fermentation of the dough pieces

- a new multifunctional belt stamping unit provides accurate and central punching at high power, e.g. for donuts or bagels

- forming station for a high product variety

- the cleanliness and accessibility of the KGV plus are ensured by the open design, generous stainless steel service doors and collecting drawers under the line

KOENIG INDUSTRY T-REX AW

The high-performance dividing and rounding machine T-Rex AW achieves with specially designed rounding ledges the high output of 100 strokes/min. The dough pieces are thereby gently and virtually smooth rounded.

Performance features:

- the dough dividing and rounding machine T-Rex AW offers a wide weight range of 25 to 70g and can operate in up to 12 rows

- max. hourly capacity of 72,000 pieces at 12-row operation

- the machine in „AW“ version (accurate weight), offers high weight accuracy and at the same time high dough protection

- the dough pieces are divided according to the proven „Rex“ principle with patented pre-portioning and gentle dough division in the dividing drum

- the dough pieces are transferred to a rounding belt and gently rounded at high speed with specially designed rounding ledges

Bakery Equipment

Bakery Equipment