Oliver

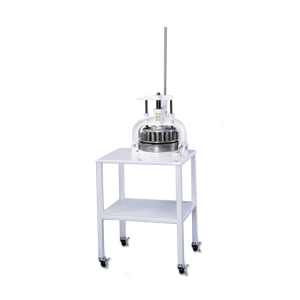

OLIVER TABLE TOP Bun Divider – Removable Head

623N Deluxe

MANUAL Dough Divider

- ideal for a variety of dough

- tool-free interchangeable dividing heads

- 9,18, and 36 par in round

- 9 part in square

- dividing head assemblies are dishwasher safe

- includes one dough pan

OLIVER Mini-Vert Air Bread Bagger 1170

1170

- mounts directly to your slicer or bench

- Complements Oliver 797 Chute-fed bread slicers

- up to 1,200 packages/hour

- product capacity: 5″ wide

- bag specifications: 9″wide minimum 32″ long maximum

- Inflates bread bag so that sliced bread can be quickly bagged

086 Semiautomatic Bag Closing Machine

086

086 Semiautomatic Bag Closing System is a versatile machine that offers a wide variety of options. The machine will close bags with the all-plastic closure and closure-labels. The 086 is also available with a printer that will print code information on the closure and/or closure-label. Featured is a power breakoff and closure advance mechanism. The simple design of the 086 is portable, jam-proof and compact, and can close bagged packages up to 30 bags per minute.

OLIVER 797 Gravity Feed Bread Slicer

797N

- Batch slicing for higher volume retail and in-store bakeries

- 32″ infeed chute with Proguard and single loaf pusher

- Proguard feature supports industry safety guidelines

- single loaf pusher gently and safely guides loaf into blades

- heavy duty castors

- Blade advantages:

- Uses the lowest cost replacement blades in the industry, contributing to low cost of ownership

- Easily replaceable, independently mounted, rust-resistant blades

OLIVER 723 Bagel & Bun Classic Slicer

723

- cleanly slices everything from sub buns to bagels with ease

- adjustable slice height setting

- separate on/off buttons

- exclusive “gentle-touch” door slows the exit of the bun to help prevent damage

- optional return chute available

OLIVER ProGuard for Gravity Feed Slicer

797

- Required by Ministry of Labor for all gravity feed bread slicers

- ProGuard helps prevent employee hands or fingers from coming into contact with the blades from loading end

- Machine can be loaded with power off and guard open

- Additional loaves must be loaded from end of guard while machine is in operation

- Auto shut-off feature when guard cage is opened

- Additional out-feed guard secures out-feed table from opening while machine is in operation

- ProGuard retrofit kit must be installed by trained and authorized service dealers

- ProGuard retrofit kit for use on machines manufactured after 1979

- ProGuard comes standard on all new 797 Gravity Feed Slicers sold into Ontario Canada

OLIVER 777 Variety Slicer

777

- Slices virtually all varieties of bread cleanly and quickly

- Compact, sturdy design is easy to use

- Automatically holds bread in place during slicing

- recommended for slicing up to 150 loaves per day

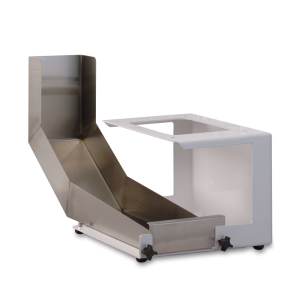

OLIVER Return Chute for 723 Bagel & Bun Slicer

RC723

- Easy to clean, durable bakery white powder coat finish on frame; stainless steel chute

- Chute holds approximately one dozen bagels

- Flip-up discharge door for efficient packaging and cleaning

- Increases counter-top space for P.O.S. or other production equipment

OLIVER 758 Front Load Duo-Slicer

758

- Two options are better than one!

- Choose two slice thickness options from four standards

- Large loaf capacity – capacity of 13” loaves per side

- Easy-to-operate, front mounted push button controls

OLIVER 732 Front Load Countertop Slicer

732

- Perfect for on-demand slicing of hard-crusted breads and soft-textured sandwich loaves

- Small footprint – less than 27” wide

- Large bread capacity – up to 16” loaves

- Easy-to-operate, with convenient, front-mounted push button controls

- Front-mounted bagging scoop that adjusts for smaller loaves makes for convenient bagging

OLIVER 302 Bagel & Bun Manual Slicer

302

- slices warm bagels or buns without crushing or deforming product

- Ensures a consistent cut for product uniformity

- Reduce risk of lacerations

- Suction cup feet to secure unit to table

- Easy insert knife guide

- Easy to clean, just place in dishwasher

OLIVER Countertop Bun Divider 623

623N

- Constructed of cast iron and cast aluminum

- Sanitary stainless steel pan included

- Model 623-36 divides dough into 36 pieces up to 4 oz. (113g) each

- Optional stand available

OLIVER Semi-Automatic Bun/Divider Rounder with removable head

625N-P

- Four machines in one

- interchangeable dividing head assemblies

- quick and easy tool-free changeover

- 36, 18, 9 and 6 part divisions

- finished dough range 1 – 26 parts

- up to 5,000 pieces/hour

- dividing head assemblies are dishwasher safe

- standard unit includes 36 part dividing head and 2 dough paddles

1002FP Semiautomatic Bag Closing Machine

1002FP

The 1002FP uses the all-plastic bag closure. Removing the closed package advances the next closure into the closing position. Speeds of up to 30 bags per minute are easily attained. Model B (CAD execution) band printer uses standard RL loks.

OLIVER / BLOEMHOF Poco Moulder

670

Compact countertop dough moulder delivers on quality, simplicity, and labor savings!

- Ideally suited for Bolillos, rolls, sub buns, hot dog buns, demi-baguettes and pan bread

- Spring loaded rollers gently stretch dough

- Dough is degassed, rolled, moulded, sealed and ready for the baking pan in seconds

- up to 3,600 pieces per hour

- Finished dough pieces from 1/2 to 18 ounce

- Infeed guarding with built in auto shut off for easy stop

- Single person operation

OLIVER / BLOEMHOF 860L MOULDER

860L-D

The Bloemhof Bread and Roll Moulder Model 860L is a simple, versatile bakery workhorse. Easily and with single person efficiency mould rolls and breads ranging from 1/2 ounce to 7 lbs.

Key Features:

- Ideal for Artisan rolls and breads, pan breads, baguettes, sub and hot dog buns, Challah and pretzels

- Adjustable speed allows for processing efficiency with both high and low hydration doughs

- finished product size 1/2 oz. to 7 lbs

- Gentle spring loaded rollers won’t tear dough

- Degas, roll, mold to a seamless finish

- From divided dough to baking pan in seconds

- Capable of processing up to 3,600 pieces per hour

- infeed guard with auomatic shut-off

- Single person operation

OLIVER / BLOEMHOF Sheeter – Mouder 4-24

4-24

The Bloemhof Simplex Sheeter/Moulder combines sheeting dough and moulding dough in one unit!

Key Features

- Moulds: Pan breads,Subs, hoagies, and hot dog buns, Challah, Pretzels and Bolillos (with optional accessories)

- (For Artisan breads, rolls see the Model 860L)

- Mould up to 3,600 pieces per hour

- Moulded product size range from 1 ounce to 4 lbs

- Sheets: Puff pastry,Danish dough, Yeast raised dough

Bakery Equipment

Bakery Equipment