Customized Solutions

GLIMEK FLOUR DUSTERS

Depending on customer requirement Glimek has different solutions for flour dusting all through the baking process. Compatible with Glimek Bread Lines.

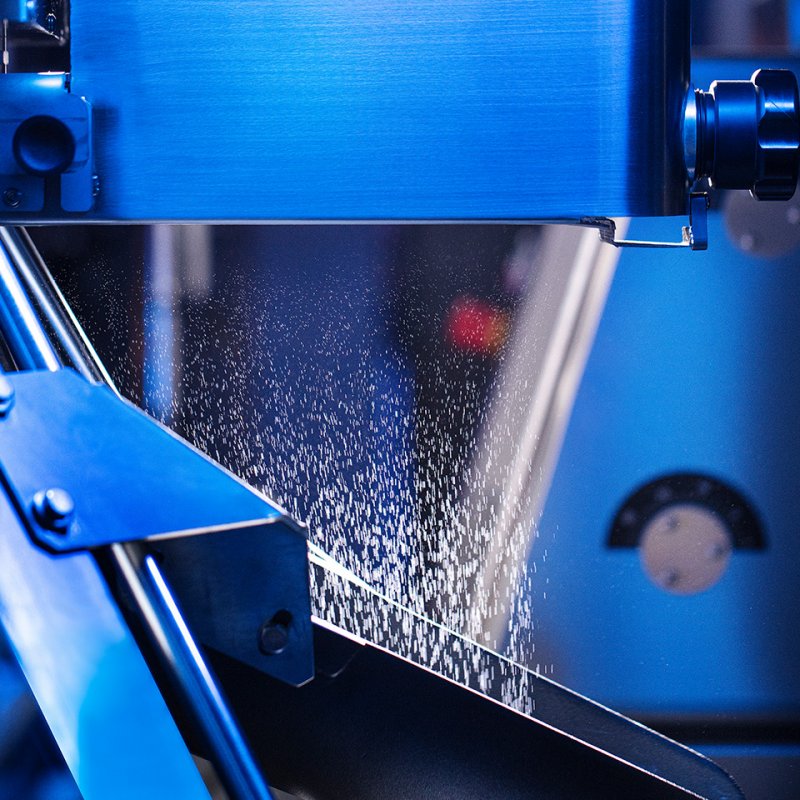

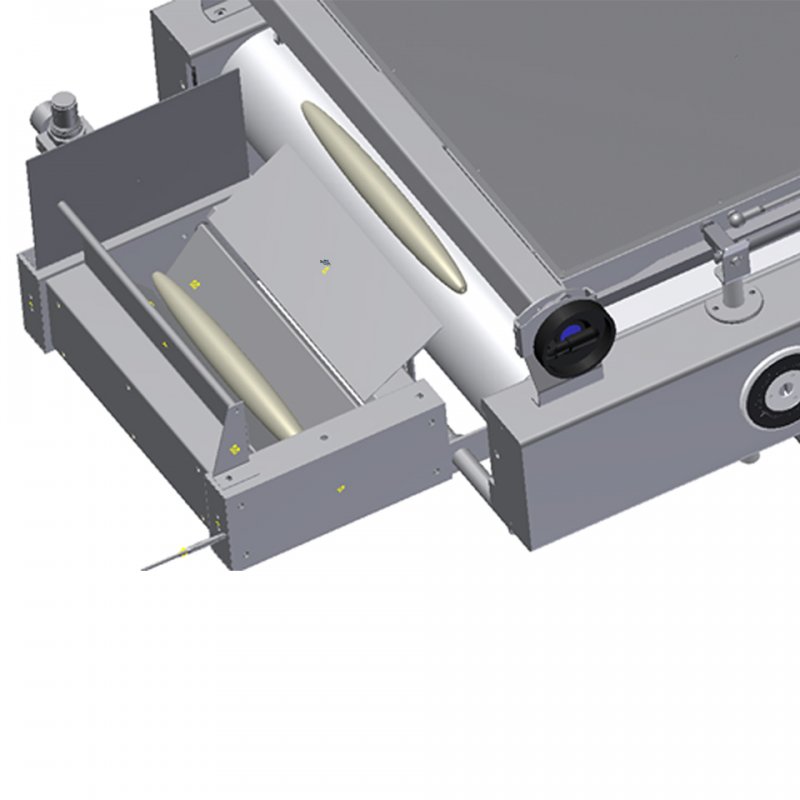

GLIMEK Coating System for Semolina Flour – COS

COS

The Glimek Semolina Flour Coating System (COS) can be integrated in Glimek bread lines when there is a need for coating of flour around the dough piece. The machine has an internal infeed conveyor, where the initial coating of the dough pieces takes place. The conveyor feeds the dough pieces into the perforated plastic tube who rotates them while coating them with granules. The tube’s angle and rotation causes the dough pieces to be fed forward.

Excess granules fall through the tube and screen into the collection box. From there, the vacuum unit returns the granules to the distribution unit.

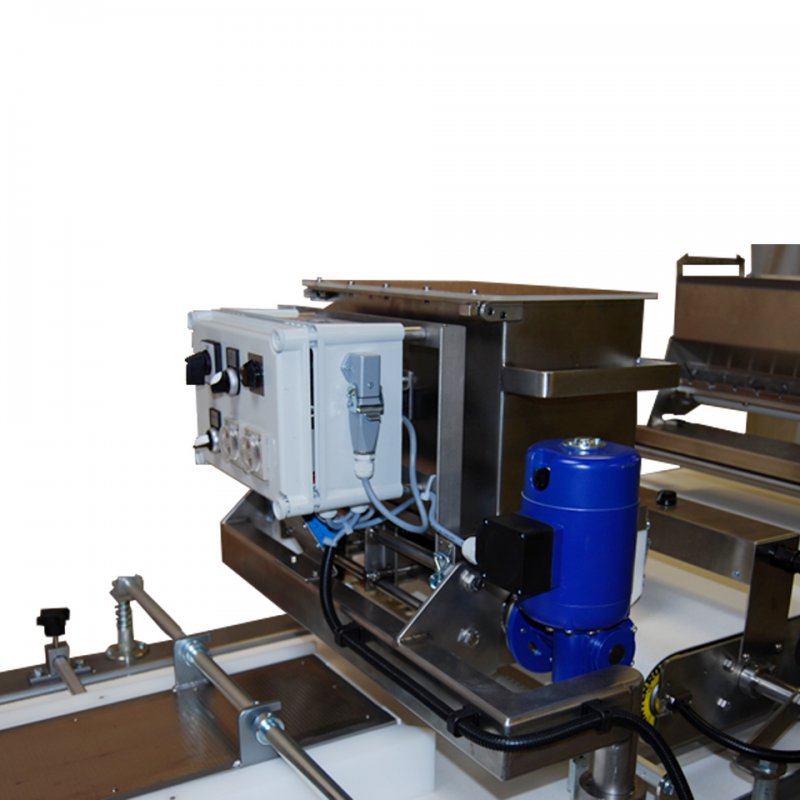

DECORATIONS UNIT – DU400

DU400

The DU400 is a decorating unit intended for the application of oats or different types of seeds, such as sesame and poppy to dough pieces. DU400 cannot be used to apply flour. The unit is normally placed between the pressure boards of the Glimek Dough Moulder MO881.

This seeding applicator is equipped with a rotating roller made of approved food grade plastic, which has indentations. The roller runs towards a brush board whereby it releases seeds onto the belt beneath, which carries the dough pieces. A photocell senses the dough pieces passing, so an individual application occurs for each dough piece. On the front of the electric cabinet are time relays for start delay, as well as the run time. It can be set for intermittent operation or for the seeding applicator to run continuously.

When the seeding applicator is mounted between the pressure board, on the Glimek Moulder MO881, the seeds are pressed towards the dough piece under the final pressure board, which means that the seeds will be pressed into the surface of the dough piece.

DOUGH PIECE SEPARATOR – DPS

DPS

Glimek Dough Piece Separator – DPS unit separates dough pieces in two rows (normally after the conical rounders) to be able to handle intermediate proofing and moulding for higher capacities.

CONVEYOR SYSTEMS – TBA, BC, MBC

Glimek offer customer adapted conveyor systems. We can design different types of conveyor systems for transportation of dough pieces, baked bread or tin sets. The design is determined together with the customer according to customer specification.

DEPOSITING UNIT

The Glimek depositing unit is fitted with two flaps to catch the dough pieces from the moulder. A photocell tells the flaps to open when the space beneath is ready. This ensures that the dough rolls are released at the correct time and in the correct position.

V-BELT CHARGING SYSTEM – VAA

VAA

Glimek V-Belt Charging System for automatic charging of dough pieces on swing tray proofer or belt proofer.

RETRACTING CHARGING SYSTEM – AA

AA

The Glimek stainless steel Retracting Charger for the automatic setting of dough pieces coming from the make-up line to the proofer conveyor belt, baking trays or similar.

BELT CONVEYOR – BC250

BC250

The BC250 Belt Conveyor, transports the dough from the Dough Piece Seperator to the Intermediate Pocket Proofer. Easy to move and clean.

Bakery Equipment

Bakery Equipment