Other

Dough Rounder Model R900T

-for the production of very round and tight dough balls

-handles 1 – 32 ounces

-36″ diameter turntable

-one person operation

New JAC Bread Slicer Model Picomatic One

-countertop slicing

-handles up to 17.3″ L x 11.8″ width x 7″ height loaf size

-available in a variety of slice thicknesses (must pick one)

New JAC Bread Slicer Model Swift 450

-capacity up to 300 loaves/hour

-handles up to 17.3″ L x 12.2″ width x 6.3″ height loaf size

-available with integrated bag blower

-available in a variety of slice thicknesses (must pick one)

Filling / Depositing

Dosing action:

- inject: 1 or 2 at a time (jelly donuts)

- deposit: 1,2 or 4 at a time (cupcakes, cakes, muffins etc)

- fill: jars, bottles, containers, etc

- Transfer

RYAN High Speed Bun / Bagel / croissant Slicer

- Model 793 Rotary Table Slicer

- up to 8000 units/hour depending on product and infeed

- single blade (793A) or dual blade (793B)

ERIKA RECORD BUN DIVIDER ROUNDER SEMI AUTOMATIC

MODEL 11-31RH

- Three lightweight, sanitary rounding plates are included

- Rounding mechanism runs in oil bath for absolutely smooth, quiet and long-lasting operation

- Sanitary cutting knives

- No oil in or above product zone

- Ships with necessary oil, which is required for the rounding mechanism

- Pressure can be determined by the operator

- Easy weight adjustment

- Minimal maintenance required

BELSHAW FRYER MODEL 718LCG GAS

- frying Area 18 inches side-to-side, 26 inches front-to-back (46 x 66 cm)

- Gas heated at 44,000 BTU/hr

- Shortening capacity 96 lbs by weight, 13 gallons by volume (44 kg/49 liters)

- Capacity 24 standard donuts, approximately 65-80 dozen donuts per hour

- Natural Gas or Liquid Propane (specify when ordering). A conversion kit is available if changeover is needed

- 120 Volts or 240 Volts, 50/60Hz, 1-phase. (specify when ordering)

- Digital electronic thermostat control

- Drain tray on right side of fryer. Can be moved to left side

- Drain and valve with exterior handle to empty shortening

- 2 cake donut frying screens with handles

- Generally suitable for Hushpuppies, Loukoumades, Funnel cakes, Elephant ears, Paczkis, Porogis, Fritters, and fried goods of all kinds

- ETL certified to NSF-4, ANSI Z83.11a and CSA1.8a.2004

- CE models available for European Union and other countries

- (Optional) Standing pilot ignition and thermocouple temperature control – no electricity required. These models are designated: 718LFG, 724FG, 734FG

- See PDF tab for more specifications

- See below for available accessories for your donut fryer

A ventilation and fire suppression hood is usually required for indoor locations.

BELSHAW DONUT FRYER MODEL 724 GAS

- Frying Area 24 x 24 inches (61 x 61 cm)

- Gas heated at 60,000 BTU/hr

- Shortening capacity 119 lbs by weight, 16 gallons by volume (54 kg/61 liters)

- Capacity 36 standard donuts, approximately 80-100 dozen donuts per hour

- Natural Gas or Liquid Propane (specify when ordering). A conversion kit is available if changeover is needed

- 120 Volts or 240 Volts, 50/60Hz, 1-phase. (specify when ordering)

- Digital electronic thermostat control

- Drain tray on right side of fryer. Can be moved to left side

- Drain and valve with exterior handle to empty shortening

- 2 cake donut frying screens with handles

- ETL certified to NSF-4, ANSI Z83.11a and CSA1.8a.2004

- CE models available for European Union and other countries

- (Optional) Standing pilot ignition and thermocouple temperature control with no electricity required. This models is designated: 724FG

- See PDF tab for more specifications

- See below for available accessories for your donut fryer

- A ventilation and fire suppression hood is usually required for indoor locations.

BELSHAW DONUT FRYER MODEL 618 ELECTRIC

- Frying Area 18 inches side-to-side x 26 inches front-to-back (46 x 66 cm)

- Shortening capacity 82 lbs by weight, 11 gallons by volume (42 kg/61 liters)

- Capacity 24 standard donuts, approximately 65-80 dozen donuts per hour

- 208-240 Volts, 50/60Hz, 1-phase or 3-phase (specify when ordering)

- Drain tray on right side of fryer (can be moved to left)

- Heavy duty elements, tiltable upwards for easy kettle cleanup

- Electronic temperature controller

- 2 cake donut frying screens

- Heavy duty drain and valve with exterior handle to empty shortening

- 208-240 Volts, 50/60 Hz, 1-phase or 3-phase (specify when ordering)

- ETL certified to UL-197, CSA C22.2 and NSF-4

- CE models available for European Union and other countries

- See PDF tab for more specifications

- See below for available accessories for your donut fryer

- A ventilation and fire suppression hood is usually required for indoor locations.

BELSHAW DONUT FRYER MODEL 624 ELECTRIC

- Frying Area 24 x 24 inches (61 x 61 cm)

- Shortening capacity 96 lbs by weight, 13 gallons by volume 44 kg/49 liters)

- Capacity 36 standard donuts, approximately 80-100 dozen donuts per hour

- 208-240 Volts, 50/60Hz, 1-phase or 3-phase (specify when ordering)

- Drain tray on right side of fryer (can be moved to left)

- Heavy duty elements, tiltable upwards for easy kettle cleanup

- Electronic heat controller

- 2 cake donut frying screens

- Heavy duty drain and valve with exterior handle to empty shortening

- ETL certified to UL-197, CSA C22.2 and NSF-4

- CE models available for European Union and other countries

- See PDF tab for more specifications

- See below for available accessories for your donut fryer

- A ventilation and fire suppression hood is usually required for indoor locations.

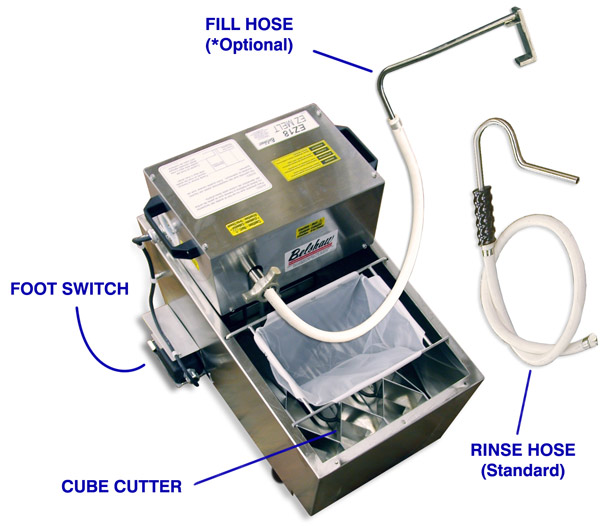

BELSHAW EZ MELT18 FILTER SYSTEM

The EZMelt18 is a recycling filter that heats shortening in the tank, with these benefits:

- If Zero Trans Fat shortenings are used, they gradually become thicker at normal bakery temperatures. This can lead to pump blockages and failures with standard filters. Using the heated EZ Melt overcomes this problem.

- Pumping reheated shortening through a fixed connection to the fryer is faster and safer than any other method, such as dropping in shortening blocks. The EZMelt does this using a refill hose (optional) which attaches directly to a Belshaw fryer.

Standard features

- Compatible with 618L, 718LCG and 718LFG fryers, Donut Robot® Mark II, and Donut Robot® Mark V.

- Can be used with any standard donut shortening including Zero Trans Fat shortening

- Heating element with factory set thermostat to 225°F/107°C. Element tilts up for easy tank cleaning. Tank itself is readily removeable.

- Long-life synthetic filter screen that needs only annual replacement under normal operating conditions.

- Heavy duty pump & motor for pumping shortening to the fryer on demand

- Heavy duty, moisture repellent foot switch for activating pump

- Cube cutter for fast melting of solid shortening blocks up to 50lbs (22.7kg)

- Hand held rinse hose with heat resistant handle

- Optional Refill Hose – allows regular topping up of fryer through a fixed connection to the fryer. The refill hose can be left in place on a Belshaw fryer at all times allowing frequent topping up of shortening level (purchased separately, see accessories)

- High-temperature limit switch

- 120V or 240V, 50 or 60 Hz, 1-Phase

- Certified by ETL to NSF Std 4, CSA C22.2, and UL 1889

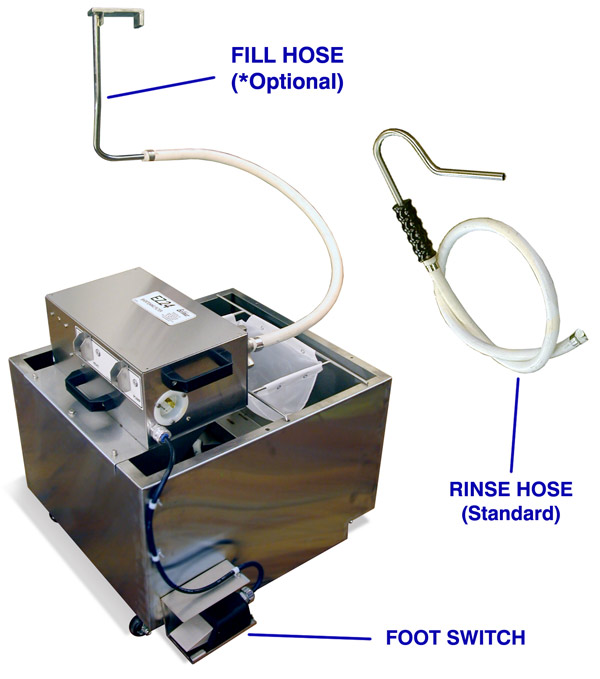

BELSHAW EZMELT 24 FILTER SYSTEM

The EZMelt24 is a recycling filter that heats shortening in the tank, with the following benefits:

- If Zero Trans Fat shortenings are used, they gradually become thicker at normal bakery temperatures. This can lead to pump blockages and failures with standard filters. Using the heated EZ Melt overcomes this problem.

- Pumping reheated shortening through a fixed connection to the fryer is faster and safer than any other method, such as dropping in shortening blocks. The EZMelt does this using a refill hose (optional) which attaches directly to a Belshaw fryer.

Standard features

- Compatible with Belshaw’s open kettle 624, 724CG and 724FG fryers.

- Can be used with any standard donut shortening including Zero Trans Fat shortening

- Heating element with factory set thermostat to 225°F/107°C. Element tilts up for easy tank cleaning. Tank itself is readily removeable.

- Long-life synthetic filter screen that needs only annual replacement under normal operating conditions.

- Heavy duty pump & motor for pumping shortening to the fryer on demand

- Heavy duty, moisture repellent foot switch for activating pump

- Cube cutter for fast melting of solid shortening blocks up to 50lbs (22.7kg)

- Hand held rinse hose with heat resistant handle

- Optional Refill Hose – allows regular topping up of fryer through a fixed connection to the fryer. The refill hose can be left in place on a Belshaw fryer at all times allowing frequent topping up of shortening level

- High-temperature limit switch

- Stainless steel frame, tank and casters

- 120V or 240V, 50 or 60 Hz, 1-Phase

- Certified by ETL to NSF Std 4, CSA C22.2, and UL 1889

BELSHAW SF18 SHORTENING FILTER

- Not recommended for trans fat free shortening!

- Uses a long-life synthetic filter screen that needs only annual replacement under normal operating conditions

- Heavy duty pump and motor for pumping back shortening to the fryer after filtering

- Foot pedal switch for activating pump

- Includes hand held rinse hose for rinsing debris from bottom of fryer and for refilling fryer

- Slides under compatible floor and tabletop fryers

- Heavy duty stainless steel frame, tank and casters

- Shortening reservoir is removeable for periodic cleaning

- SF Shortening Filters are not designed for Zero Trans Fat shortenings. These shortenings solidify as they cool down, sometimes causing blockages in the filter pump.

- Belshaw recommends the EZMelt18 Melter-Filter for Zero Trans Fat shortenings. The EZMelt contains a heating element to liquify any shortening.

- 120V or 240V, 50 or 60 Hz, 1-Phase

- Certified by ETL to NSF Std 4, CSA C22.2, and UL 1889

BELSHAW SF24 SHORTENING FILTER

- Not recommended for trans fat free shortening

- Uses a long-life synthetic filter screen that needs only annual replacement under normal operating conditions

- Heavy duty pump and motor for pumping back shortening to the fryer after filtering

- Foot pedal switch for activating pump

- Includes hand held rinse hose for rinsing debris from bottom of fryer and for refilling fryer

- Slides under compatible floor and tabletop fryers

- Heavy duty stainless steel frame, tank and casters

- Shortening reservoir is removeable for periodic cleaning

- SF Shortening Filters are not designed for Zero Trans Fat shortenings. These shortenings solidify as they cool down, sometimes causing blockages in the filter pump.

- Belshaw recommends the EZMelt24 Melter-Filter for Zero Trans Fat shortenings. The EZMelt contains a heating element to liquify any shortening.

- 120V or 240V, 50 or 60 Hz, 1-Phase

- Certified by ETL to NSF Std 4, CSA C22.2, and UL 1889

BELSHAW FILTER FLOW SIPHON

Compatible with 616B, Cut-N-Fry, Donut Robot Mark II, Mark II GP, Mark II Gas, Mark II GP Gas, Mark V, Mark V GP Fryers.

The Filter-Flo is a dependable heavy duty siphon that extracts and filters shortening from fryers, in situations where there is no room for a built-in drain, or if your fryer has no built-in drain. A squeeze of the large bulb starts the flow which can empty a Mark II in a few minutes. A reusable cloth filter cleans as the liquid passes through. Note: the Filter-Flo requires a customer-supplied leakproof container for filtered shortening to pour into. Filter-Flo is not needed if you already have a shortening filter such as SF or EZMelt

BELSHAW DONUT ROBOT MARK II ELECTRIC DONUT MAKER

- All electric donut machine, capacity approximately 37 dozen standard size donuts per hour

- Deposits 2 standard donuts per conveyor row. A half-speed switch cuts output to 1 per row

- Makes consistent, well rounded cake donuts with synchronized cake donut depositor

- Makes excellent yeast raised donuts with the addition of optional Feed Table, Trays, and Cloths (see accessories)

- Dial with generous range for adjusting size of cake donut

- Makes mini donuts with optional mini donut hopper and plunger, which will deposit 4 minis per row. (Part # MK-1502-1, see accessories). Mini donut capacity will be approximately 109 dozen/hour

- Electronic temperature controller – maintains temperature normally within ±1 degree

- Speed is adjustable by dial on control panel

- Outfeed belt dispenses donuts into collection device such as Roto-Cooler

- Heavy duty elements which tilt upward when cleaning

- High temperature shut-down switch

- Hopper, plunger, conveyor, and kettle are all removable for easy cleaning

- 1-9/16 inch Plain Plunger for Ring donuts

- Single and 3 phase voltages available for all countries

- North America models certified to UL, NSF and CSA

- Machines shipped to European Union conform to CE regulations

- Australia/NZ, Japan, and other worldwide models available

- See below for accessories and options such as Roto-Cooler and EZMelt Filtration System

- Compatible with Insider Ventless Cabinet

BELSHAW DONUT ROBOT MARK II GAS DONUT MAKER

- Gas heated donut machine with electrically powered conveyor and depositor

- Capacity 350 donuts per hour (29 dozen) at fry time 120sec

- Requires only 360 Watts of power for conveyor and despositor

- Deposits 2 standard size donuts per conveyor row

- 40,000 BTU per hour

- Natural Gas and Liquid Propane models available (specify at purchase)

- Makes consistent, well rounded donuts with synchronized depositor

- Makes excellent yeast raised donuts with the addition of optional Feed Table, Trays, and Cloths

- Makes mini donuts with optional mini donut hopper and plunger, which will deposit 4 mini donuts per row. (Part # MK-1502-1, see accessories). Mini donut capacity will be approximately 700 minis/hour (59 dozen) at fry time 90sec

- For faster mini donut production, choose Mark II GP Gas

- Speed is adjustable by dial on control panel

- Size is adjustable by dial on depositor

- Automatic conveyor with automatic donut turner

- Outfeed belt dispenses donuts into collection device such as Roto-Cooler

- High temperature shut-down switch

- Hopper, plunger, and conveyor, and kettle are all removable for easy cleaning

- See below for accessories and options

- Not compatible with Insider Ventless Cabinet (only compatible with electric models)

MERAND ROLLER DUO – ECCENTRIC ROUNDER & MOULDER

Machine for rounding loaves, balls and short breads with weight from 76 grams up to 4000 grams (rounding).

- Steel frame

- motorization with two independent motors (one for the rounder, one for the shaper)

- loaves and short breads shaper with laminating roll and adjustable table

- available in 78cm and 120 cm

Deighton FORMATIC Cookie Machine

Able to handle a variety of batters with custom drums available providing shape/weight/size possibilities.

Removable Bowl Spiral Mixer

Model Gemma

-2 motors, 2 speed each

-choice of two panels (manual controls or user panel)

-temperature probe

-efficient hydraulic system

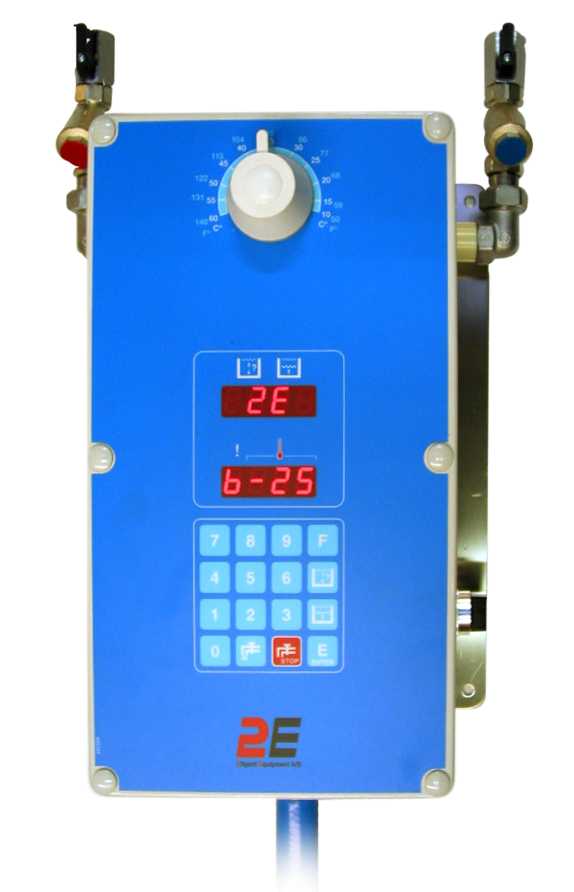

2E Ellegard

The B25 is designed for operation in bakeries requiring capacities in the area of 25 l/min (at an inlet pressure of approx. 3 bar) and an accurate temperature control.

- The B25 is easy and simple to operate.

- The required water quantity is set via the key-pad which is smooth and very easy to clean.

- The B25 can memorize up to 3 different water quantities/programs. An intermediate stop can be entered in each program.

- Temperature is set manually by means of a handle. To displays shows the set water quantity and temperature, respectively, as well as any set intermediate stops, and during metering the actual quantity is continuously displayed. By means of a button for automatic intermediate stop, the quantity of water can be divided into two portions allowing for a pre-mix.

- The water mixer has a repeat function meaning that you only have to press a button to repeat the latest metered quantity.

- Any interruptions of operation are easily identified by means of codes given in the temperature display.

CEPI Silsystem

Indor silo series SILSYSTEM for food stuff in antistatic trevira fabric with built-in filtering roof. Silo is custom made and suited for powders of density up to 1,3 kg/liter. The modular structure in galvanized steel allows quick assembling and disassembling. CAPACITY: 1-70 Mc.

TECHNICAL DETAILS:

- supporting structure in electical zinc-coated normalprophylated with wedge for quick assembling and disassembling;

- body in ANTISTATIC trevira fabric suited for the storing of food stuff according to the CE norms for the security of powder treatmemt. It’s strongly reccommended when natural oxygenation of the material is required. There is no condensation;

- designed for installation in sheltered environments with natural or forced ventilation.

ACCESSORIES:

- Powder recovering FILTERS compliant with CE norms;

- Minimum and mazimum level probes;

- Weighing system with cells.

CEPI Big Bag

Indoor Big Bag Unloading System in painted or stainless steel, built with material suited to the storing and conveying of food stuff. Eases the emptying of Big Bags.

Modular structures in stainless steel suitable for all room solutions.

TECHNICAL DETAILS AND STANDARD EQUIPMENT:

- Cylindrical shape with rectangular enlarged hemisphere to ease the placement and movement of bags;

- Base trunk completed with 4 supporting feet in painted steel; supports future anchoring to the ground;

- Telescopic regulation of the Big Bag supporting structure to ease support;

- Epossidic baking varnish.

CEPI Micro

Silos are built with materials suitable for the storing of solid food stuff. Integrated dosing groups for the managment of microingredients. Structures are modular and adaptable to all room solutions, and always allow enlargments and future changes. Ingredients loading is performed manually by discharging the bags inside the hopper or by sucking the products directly from the bag from the ground level.

PATENTED MICRODISPENSERS TRIMIX: Allow the volumetric dosing of powder products. Can be used with homogenizer-fluidizer with the most difficult products. Interchangeable between products. Hoppers are completely modular therefore the capacity increases by bsimply adding a module to the base block. Group is entirely closed to avoid pollution of the stored material and powder leaks.

CEPI Silo Accessories

| Loading cell Built in high precision tin stainless steel, with anchoring bolts, 5 meters connecting cable and flexible support. Standard (10, 25, 50, 100, 150, 250, 500, 750, 1000, 1500 Kg) and custom weight. |

|

| Antiexplosion hatch For silos and hoppers, built in stainless steel and equipped with limit switch to signal breaking. |

|

| Capacitive probe Detects maximum and minimum level, with feeding: 24 V, contact NA in exchange, screw for regulation and calibration, joints and props and 1 meter electrical cable. |

|

| Security valve Mechanic for silo, built in stainless steel AISI 304. Maximum pressure: 270 mm circa, minimum pressure: 20 mm circa. Equipped with regulation bars with sigil and protection carter in steel. |

|

| Cepatic security valve Connected to silos, allows active control of pressure in the loading from tank to silo. |

|

Filters

|

CEPI Conveyance Accessories

CEPI Extraction from silos and hoppers Accessories

LBC BakerSeries Roll-in Proofer (1 Door)

LRP1

- Heavy duty stainless steel exterior with 300 Series stainless steel interior and aluminized steel top

- Walls Ceilings and door are foam insulated

- Modular wall and ceiling panels with cam lock construction

- Rapid responding air-wash heat and humidity system

- High capacity refrigeration system with epoxy coated evaporator coils

- 208/240 VAC single or 3-phase power, field convertible

LBC BakerSeries Roll-in Proofer (2 Door)

LRP2

- Heavy duty stainless steel exterior with 300 Series stainless steel interior and aluminized steel top

- Walls Ceilings and door are foam insulated

- Modular wall and ceiling panels with cam lock construction

- Rapid responding air-wash heat and humidity system

- High capacity refrigeration system with epoxy coated evaporator coils

- 208/240 VAC single or 3-phase power, field convertible

Precisma Manual spray unit

- Very economic on release agent

- Precise dosage of application quantity possible

- Film evenly distributed over the entire surface

- For all conventional release agents and cutting oils

- Easy to use, low-maintenance and easy to clean

- Compact design for mobile operation

- Complies with current hygiene standards

LBC BakerSeries Roll-in High Output Retarder Proofer (1 Door)

LRPR1

- Heavy duty stainless steel exterior with 300 Series stainless steel interior and aluminized steel top

- Walls Ceilings and door are foam insulated

- Modular wall and ceiling panels with cam lock construction

- Rapid responding air-wash heat and humidity system

- High capacity refrigeration system with epoxy coated evaporator coils

- 208/240 VAC single or 3-phase power, field convertible

- Optional remote condensers

- Refrigeration components compatible with R404A refrigerant

Harvest Lye Application Machine

DB240A4

Section 1: manual infeed (rolls) or flipper device (pretzels)

Section 2: 3 lye “showers”

Section 3: automatic outfeed

- stainless steel construction

- capacity: approx. 240 boards / hour with 2 operators

- lye tank capacity: appr. 135 liters

- lye heating 6 KW for quick heating

- conveyor width: 780 mm

- overall width: apprx. 1,000mm

- overall working length: 2,400mm

- working height: appr. 1,100mm

LBC BakerSeries Roll-in High Output Retarder Proofer (2 Door)

LRPR2

- Heavy duty stainless steel exterior with 300 Series stainless steel interior and aluminized steel top

- Walls Ceilings and door are foam insulated

- Modular wall and ceiling panels with cam lock construction

- Rapid responding air-wash heat and humidity system

- High capacity refrigeration system with epoxy coated evaporator coils

- 208/240 VAC single or 3-phase power, field convertible

- Optional remote condensers

- Refrigeration components compatible with R404A refrigerant

MERAND DIVA HYDRAULIC DIVIDER

Hydraulic Divider Options

- 20 divisions – Square tank

- 20 divisions – Round Tank

- Fat dough press

Harvest / Mussana Cream Machine

- Built to achieve the highest standards of hygiene and operation

- Automatic electronic operation with several pre-set portion control modes

- Insulated intensive cooling of the whipping system ensures that cream remains chilled from the container right through to the decorating nozzle

- Easy cleaning and sterilizing of machine with water temperatures to 80″ C

- Maximum volume of whipping cream due to “double labyrinth” VZA stainless steel whipping system

- Fully automatic temperature control

- CFC free refrigeration system

- Removable VZA stainless steel cream container

- Tested according to DIN 10507 (food hygiene) standard

- Hygiene certificate included with each machine

- Manufactured by Hans Kratt

- Watch video of how easy it is to perform a daily cleaning using the Mussana Microclean Powder!

Harvest / BOYENS Jelly Sprayer/Glazer

- Digital readout

- Maintenance-free technology

- Rapid heat-up time

- No fluctuations in temperature

- No water bath technology

- Hose heated right up to the spray gun

- Stronger heating

- Stainless steel execution

- Includes a special dry running heater

TEKNO (Logiuduce Forni) – MiniStar Stone Hearth Deck Oven

- using Vapor Tube Technology — giving even heat distribution and retention.

- Separate steam generators for each individual baking chamber positioned in the lower part of the oven in direct contact with the hot air flow generated by the burner. They guarantee large quantities of steam with very fast recovery times.

- full glass doors for easy viewing.

- Available with integrated loader/unloaders.

- Stainless steel front and external covering.

- Quick recovery and temperature change.

- Burner is front mounted.

- Available in gas or diesel oil versions.

- Low consumption of fuel and energy.

TEKNO (Logiuduce Forni)

- New double pulley belt transmission

- Heavy-thickness steel frame, wheels mounted

- Digital or electromechanic control panel

- Bowl safety guard in ABS, closed type or with stainless steel grid

MERAND DIVIDER / SHAPER DIVA 2 – WITH OPTIONAL DIV-X OR ATOUPAIN

- Hydraulic divider MERAND Diva has a square tank, therefore you can divide the dough into 20 equal divisions.

- Its strong design guarantees the MERAND Dough Divider reliability.

- Every detail is designed to provide comfort, make it easy to clean and very respectful of dough.

- Perfectly adapted from small dough pieces of 150gr to big dough pieces of 1Kg, thanks to its huge tank that can be loaded up to 20Kg. (Hydraulic Divider mode)

- This divider can also be upgraded to become a divider-shaper MERAND.

- Exclusive MERAND Systems can be added to fit extra requirements such as : APF®, Non Flour Splatter / FlourBox®, removable flourbox / Variopress®, pressure sensor according to dough type / EasyDoors®, safe and easy cleaning system without tools / FlexiTable®, foldable worktable.

Product Specifications:

| Mode | # of pieces | total tank capacity* |

|---|---|---|

| Hydraulic Mode: | 20 division | up to 20 kg dough |

| Baguette Mode: | 8 or 10 division | up to 3.5 kg dough |

| Div-X Model: | see grid chart | up to 7 kg dough |

*tank capacity is dependent on dough type/density and are guidelines only. Note in Div X mode the variety of grids will determine your quantity of dough pieces and total dough capacity.

MERAND Tregor VERTICAL MOULDER

Features

Machine to roll and to shape dough balls with weight from 50 grams (1.76 oz) to 1 450 grams (3.19 lb). The Production rate is up to 1 800 parts per hour depending on the dough ball weight.

- 2 pointed selector for laminating and lengthening adjusting.

- Laminating system between 3 rollers

- Stretching system between two moving belts (compact machine).

- Easy dismantling of the 2 belts within 25 mn, 5 mn for the back belt

- Hinged safety hopper, and easy removable scrapers

Fokus LFKR Annular Hearth Deck Oven

EVENNESS and QUALITY IN BAKING, combined to an extraordinary rapidity on temperature variation are the results of the technology applied to the traditional system of the annular steam tube ovens.

- External and single cross Manessman tubes, resistant to high pressure have an external diameter of 27 mm and thickness of 4 mm.

- The absence of bricks and cement in the fire room allows to reduce the weight and slightly the dimensions of the oven itself. Hot air flues are manufactured of refractory steel cylinders, high temperature resisting. All tube assembly is insulated with a light but of high coefficient of insulation material. Quickly reacting where an increase of temperature is demanded and above all very economical in fuel consumption compared to other steam tube ovens.

- Steam generators are positioned in the middle of the hot air conduct, thus

producing a large quantity of steam. - Individual steam generators for each deck.

- 2, 3 & 4 door design, up to 5 decks.

- Tempered glass doors with counterweight.

- available with manual, semi-automatic and automatic loaders

Harvest Petite Line

Highly customizable make-up tables, designed to be easy to use and effective, with high output, rapid format change, a simple sanitation.

- Very compact and easy to use

- Allows you to get industrial productions of various products: half moons, danish, strudel, flutes, ears, vol au vents

- The quick tool-hooking system, a wide variety of pumps and distributors suitable for every type of filling

- many decorating and forming accessories applicable to any type of line, the automatic panning solutions and automatic proofers/freezers loading systems

Bakery Equipment

Bakery Equipment