Metering

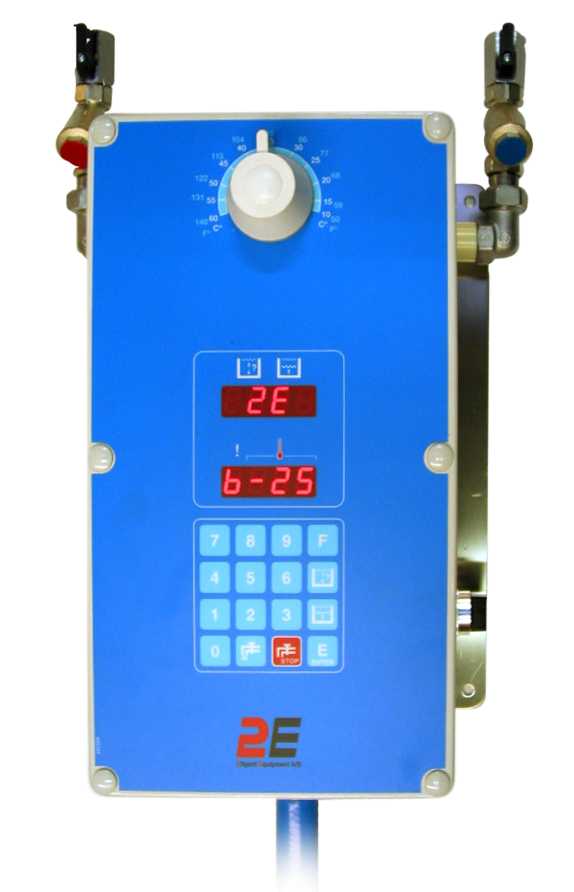

2E Ellegard

The B25 is designed for operation in bakeries requiring capacities in the area of 25 l/min (at an inlet pressure of approx. 3 bar) and an accurate temperature control.

- The B25 is easy and simple to operate.

- The required water quantity is set via the key-pad which is smooth and very easy to clean.

- The B25 can memorize up to 3 different water quantities/programs. An intermediate stop can be entered in each program.

- Temperature is set manually by means of a handle. To displays shows the set water quantity and temperature, respectively, as well as any set intermediate stops, and during metering the actual quantity is continuously displayed. By means of a button for automatic intermediate stop, the quantity of water can be divided into two portions allowing for a pre-mix.

- The water mixer has a repeat function meaning that you only have to press a button to repeat the latest metered quantity.

- Any interruptions of operation are easily identified by means of codes given in the temperature display.

CEPI Silsystem

Indor silo series SILSYSTEM for food stuff in antistatic trevira fabric with built-in filtering roof. Silo is custom made and suited for powders of density up to 1,3 kg/liter. The modular structure in galvanized steel allows quick assembling and disassembling. CAPACITY: 1-70 Mc.

TECHNICAL DETAILS:

- supporting structure in electical zinc-coated normalprophylated with wedge for quick assembling and disassembling;

- body in ANTISTATIC trevira fabric suited for the storing of food stuff according to the CE norms for the security of powder treatmemt. It’s strongly reccommended when natural oxygenation of the material is required. There is no condensation;

- designed for installation in sheltered environments with natural or forced ventilation.

ACCESSORIES:

- Powder recovering FILTERS compliant with CE norms;

- Minimum and mazimum level probes;

- Weighing system with cells.

CEPI Big Bag

Indoor Big Bag Unloading System in painted or stainless steel, built with material suited to the storing and conveying of food stuff. Eases the emptying of Big Bags.

Modular structures in stainless steel suitable for all room solutions.

TECHNICAL DETAILS AND STANDARD EQUIPMENT:

- Cylindrical shape with rectangular enlarged hemisphere to ease the placement and movement of bags;

- Base trunk completed with 4 supporting feet in painted steel; supports future anchoring to the ground;

- Telescopic regulation of the Big Bag supporting structure to ease support;

- Epossidic baking varnish.

CEPI Micro

Silos are built with materials suitable for the storing of solid food stuff. Integrated dosing groups for the managment of microingredients. Structures are modular and adaptable to all room solutions, and always allow enlargments and future changes. Ingredients loading is performed manually by discharging the bags inside the hopper or by sucking the products directly from the bag from the ground level.

PATENTED MICRODISPENSERS TRIMIX: Allow the volumetric dosing of powder products. Can be used with homogenizer-fluidizer with the most difficult products. Interchangeable between products. Hoppers are completely modular therefore the capacity increases by bsimply adding a module to the base block. Group is entirely closed to avoid pollution of the stored material and powder leaks.

CEPI Silo Accessories

| Loading cell Built in high precision tin stainless steel, with anchoring bolts, 5 meters connecting cable and flexible support. Standard (10, 25, 50, 100, 150, 250, 500, 750, 1000, 1500 Kg) and custom weight. |

|

| Antiexplosion hatch For silos and hoppers, built in stainless steel and equipped with limit switch to signal breaking. |

|

| Capacitive probe Detects maximum and minimum level, with feeding: 24 V, contact NA in exchange, screw for regulation and calibration, joints and props and 1 meter electrical cable. |

|

| Security valve Mechanic for silo, built in stainless steel AISI 304. Maximum pressure: 270 mm circa, minimum pressure: 20 mm circa. Equipped with regulation bars with sigil and protection carter in steel. |

|

| Cepatic security valve Connected to silos, allows active control of pressure in the loading from tank to silo. |

|

Filters

|

CEPI Conveyance Accessories

CEPI Extraction from silos and hoppers Accessories

Bakery Equipment

Bakery Equipment