Glimek

GLIMEK FLOUR DUSTERS

Depending on customer requirement Glimek has different solutions for flour dusting all through the baking process. Compatible with Glimek Bread Lines.

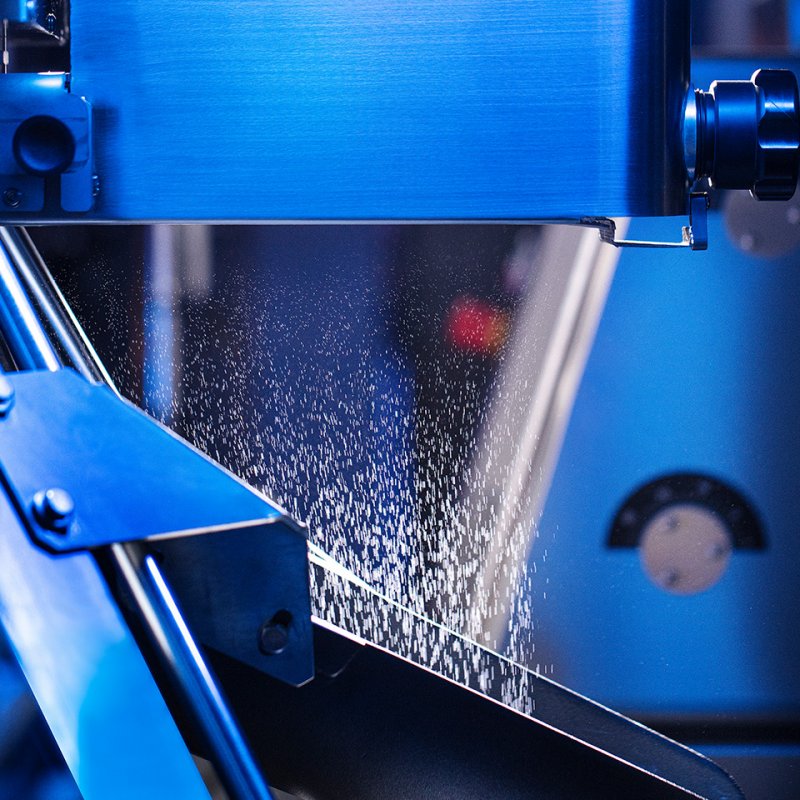

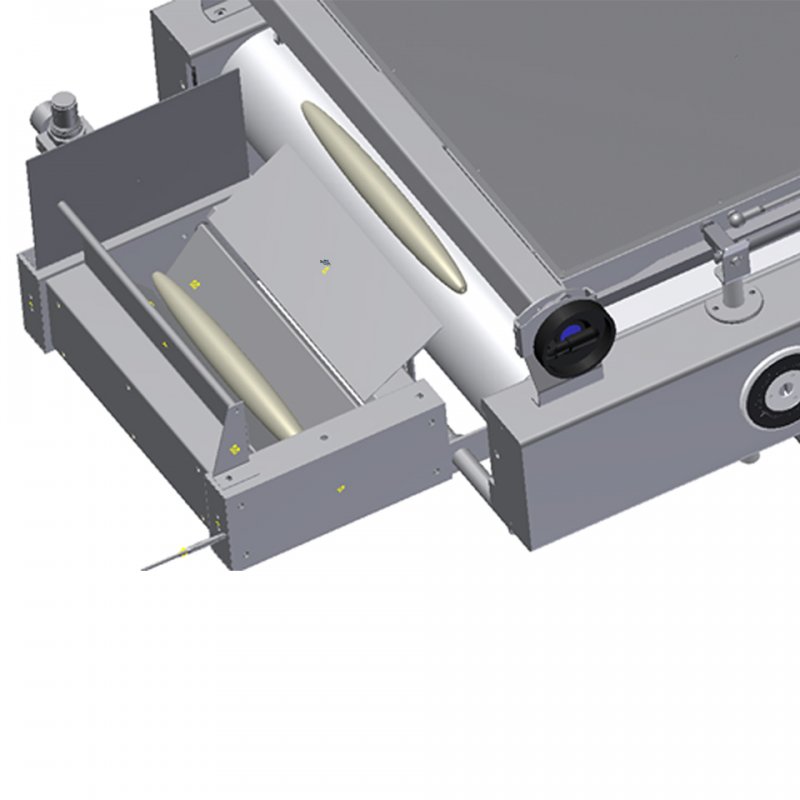

GLIMEK Coating System for Semolina Flour – COS

COS

The Glimek Semolina Flour Coating System (COS) can be integrated in Glimek bread lines when there is a need for coating of flour around the dough piece. The machine has an internal infeed conveyor, where the initial coating of the dough pieces takes place. The conveyor feeds the dough pieces into the perforated plastic tube who rotates them while coating them with granules. The tube’s angle and rotation causes the dough pieces to be fed forward.

Excess granules fall through the tube and screen into the collection box. From there, the vacuum unit returns the granules to the distribution unit.

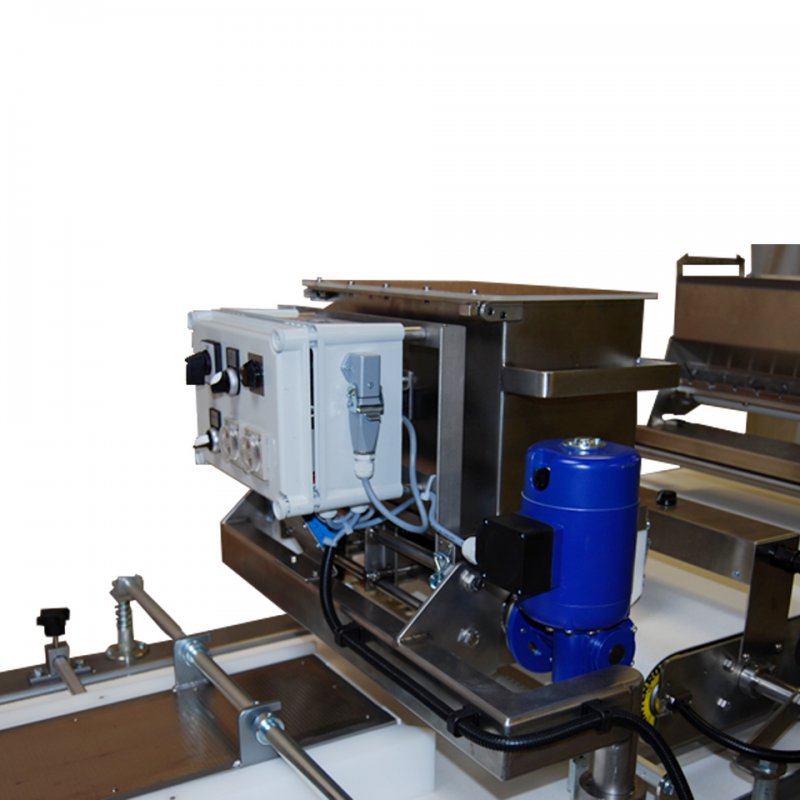

DECORATIONS UNIT – DU400

DU400

The DU400 is a decorating unit intended for the application of oats or different types of seeds, such as sesame and poppy to dough pieces. DU400 cannot be used to apply flour. The unit is normally placed between the pressure boards of the Glimek Dough Moulder MO881.

This seeding applicator is equipped with a rotating roller made of approved food grade plastic, which has indentations. The roller runs towards a brush board whereby it releases seeds onto the belt beneath, which carries the dough pieces. A photocell senses the dough pieces passing, so an individual application occurs for each dough piece. On the front of the electric cabinet are time relays for start delay, as well as the run time. It can be set for intermittent operation or for the seeding applicator to run continuously.

When the seeding applicator is mounted between the pressure board, on the Glimek Moulder MO881, the seeds are pressed towards the dough piece under the final pressure board, which means that the seeds will be pressed into the surface of the dough piece.

DOUGH PIECE SEPARATOR – DPS

DPS

Glimek Dough Piece Separator – DPS unit separates dough pieces in two rows (normally after the conical rounders) to be able to handle intermediate proofing and moulding for higher capacities.

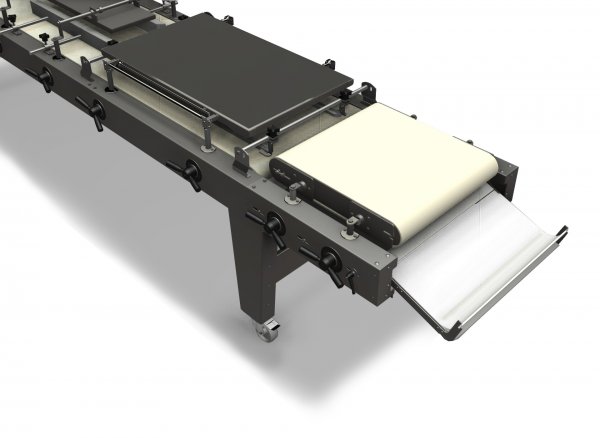

CONVEYOR SYSTEMS – TBA, BC, MBC

Glimek offer customer adapted conveyor systems. We can design different types of conveyor systems for transportation of dough pieces, baked bread or tin sets. The design is determined together with the customer according to customer specification.

DEPOSITING UNIT

The Glimek depositing unit is fitted with two flaps to catch the dough pieces from the moulder. A photocell tells the flaps to open when the space beneath is ready. This ensures that the dough rolls are released at the correct time and in the correct position.

V-BELT CHARGING SYSTEM – VAA

VAA

Glimek V-Belt Charging System for automatic charging of dough pieces on swing tray proofer or belt proofer.

RETRACTING CHARGING SYSTEM – AA

AA

The Glimek stainless steel Retracting Charger for the automatic setting of dough pieces coming from the make-up line to the proofer conveyor belt, baking trays or similar.

BELT CONVEYOR – BC250

BC250

The BC250 Belt Conveyor, transports the dough from the Dough Piece Seperator to the Intermediate Pocket Proofer. Easy to move and clean.

INTERMEDIATE POCKET PROOFER – IPP 1272

IPP 1272

One of the most flexible pocket proofers on the market. For 6, 8, 10 or 12 pockets. Modulated for easy adaption in height and depth, available in standard models from 132 up to 1128 effective pockets. Solid construction in stainless steel materials.

GLIMEK SD-180 Suction Dough Divider

SD-180

- Weight range, 3 versions, 35 up to 2300 grams

- Variable speed with frequency converter

- Capacity 750 up to 1800 pieces per hour as standard

- Stainless steel dough knife

- Unique emptying function (hopper reaches all the way down to the knife)

- Gentle dough handling

- Easy handling and cleaning – all covers are in stainless steel and are removable

- 100 liter stainless steel hopper as standard

- 225 liter stainless steel hopper (optional)

- Non stick coated hopper (optional)

- 17 liter oil reservoir, easy to fill

- Extremely silent 72 dB(A)

GLIMEK CR400 CONICAL DOUGH ROUNDER

CR400

- Centrally adjustable rounding tracks

- Capacity up to 4000 pieces per hour, this is subject to dough weight and dough characteristics

- Weight range from 30 up to 1800 grams, this is subject to dough characteristics and capacity

- Non-stick coated cone and tracks for better rounding

- Rounding length up to 4 meters

- Operation panel easy accessible from both sides

- Easy to clean

GLIMEK IPP Intermediate Pocket Prover

IPP

- Three different infeed systems

Adapted to customer needs - Dual infeed

For capacity up to 3000 pcs/h - Electrical cabinet

The dough divider, conical rounder and moulder is connected to the IPP - IPP pocket prover

The IPP is a modular pocket prover that is adapted to the customers needs when it comes to capacity per hour and resting time.

The standard execution consists of 6, 8 or 10 cups per swing, A robust construction, swings and cover plates and manufactured in stainless steel

GLIMEK MO300 Dough Moulder

MO300

The MO300 is available with a wide variety of options to suit the customers needs.

- Centrally adjustable infeed

Enables a correct positioning of the dough piece - Two pair of 400mm wide adjustable pressure rollers

With spring loaded scrapers for easy cleaning - Collection tray with two positions

Enables straight line outfeed - Capacity range up to 3000 dough pieces per hour

- Weight range from 30 up to 1800 grams

- Working width up to 650 mm

GLIMEK Flexible Bread Line – Bread Line 180

180

The Flexible bread line is very user friendly and flexible with a high capacity and efficiency.

It handles a wide variety of dough types and sizes which makes the bread line very flexible and efficient. The Flexible bread line consists of the following freestanding machines:

- SD-180 Dough Divider

Weight range from 120 to 1600 g, variable speed with frequency converter for 750 up to 1800 pcs/h, 100 liter stainless steel hopper with non stick coating. The SD-180 in the picture is equipped with a flour duster. - CR-400 Conical Rounder

The CR-400 has centrally adjustable non-stick coated tracks, infeed at 6h, outfeed at 12 h and outfeed chute and mechanical flour duster. - IPP 6/22 Intermediate Pocket Prover

Intermediate pocket prover with 132 effective pockets, single infeed V-belt conveyor. Its equipped with photocell controlled non-stick coated infeed conveyor with continuous pocket prover drive. The prover has variable speed and the electric control panel is situated under the projecting overhang for easy control. The IPP has power supply for the divider, conical rounder and the moulder. Max proving time is 4,3 minutes at 1800 pcs/h. - MO-300 Moulder

The moulder has centrally adjustable infeed in the hopper and two pair of rollers, the pressure board is 650X1100mm with a collection tray to collect the dough pieces.

GLIMEK – Bread Line 180 Direct

The Straight Dough Line is specially made for producing bread without need for an intermediate proving time. Its a very compact dough line with capacity of up to 1800 pieces per hour and a with a weight range of 120 up to 1600 grams.

- Straight dough line Eco

There is also a Eco version of the straight dough line where the conical rounder is replaced by a hander up system that is mounted on the extended outfeed conveyor of the divider. - SD-180 Suction Dough Divider

Weight range from 120 to 1600 g, variable speed with frequency converter for 750 up to 1800 pcs/h, 100 liter stainless steel hopper with non stick coating. - CR-400 Conical Rounder

The CR-400 has centrally adjustable non-stick coated tracks, infeed at 6h, outfeed at 12 h and outfeed chute and mechanical flour duster. - CE-100 Cup Elevator

The cup elevator is mounted on the moulder, this transports the dough pieces from the rounder (or hander up) to the moulder - MO-300 Moulder

The moulder has centrally adjustable infeed in the hopper and two pair of rollers, the pressure board is 650X1100mm with a collection tray to collect the dough pieces.

GLIMEK CE-100 Cup Elevator

CE-100

A step by step elevator for transporting dough pieces from the rounder into the moulder.

- Elevator mounted on MO-300

- The conveyor belt, 200mm wide, has riveted cups every 300 mm

- The timing of each dough piece is controlled by a photocell

- The infeed hopper guides the dough piece int an empty cup

- Capacity up to 2000 pieces/hour

- Weight range: approximately 100-1500 grams

GLIMEK CE-300 Cup Elevator

CE-300

- The conveyor belt, 200mm wide, has riveted cups on every 300mm

- The timing of each dough piece is controlled by a photocell

- The infeed hopper guides the dough piece into an empty cup

- Capacity: up to 2000 pieces/hour

- Weight range: apprx. 100 – 1500 grams

GLIMEK CE-500 Cup Elevator

CE-500

- The timing of each dough piece is controlled by a photocell

- The infeed hopper guides the dough piece into an empty cup

- Additional distributing height (optional)

- Capacity: up to 3600 pieces//hour

GLIMEK BL Bowl Lift

MODEL BL

With a capacity to lift up to 600 kilos this bowl lift is very versatile (removable bowl incl. dough).

The bowl lift can be designed to empty the bowl to the left or right which makes it adaptable to the bakery layout.

GLIMEK BH Bulk Hopper

MODEL BH

With a volume of 575 liters as standard this bulk hopper is very efficient.

- Hopper in stainless steel – painted frame included

- Pneumatic controlled dough knife with a width of 400mm as standard (other sizes on request)

- Automatic dosing device, photocell controlled which creates an even dough level in the divider hopper and better weight accuracy

- 575 liter volume – 350 kilo dough

- Sliding plate on top of bulk hopper is included

- Support bare between Bowl lift and Bulk hopper when delivered together

- Designed to work with dividers from other suppliers (on request)

GLIMEK SD-300 Suction Dough Divider

SD-300

Features

- Weight range: 1-pocket 150 to 2300 grams, 2-pocket 40 to 1000 grams

- Variable speed with frequency converter

- Capacity: 1-pocket from 750 up to 1500 pieces per hour, 2-pocket from 1500 up to 3000 pieces per hour

- Dough knife in stainless steel

- Unique emptying function (hopper reaches down to the dough knife)

- Gentle dough handling

- Dough chambers in high quality Ni.resist steel ensure high weight accuracy and long durability

- PLC touch screen

- Heavy duty construction

- 100 liter stainless steel hopper as standard

- 225 liter stainless steel hopper (optional)

- Non stick coated hopper (optional)

- Easy handling and cleaning since all covers are in stainless steel and removable

- 11 liter oil reserve, easy to fill

- Stainless steel execution

- Available with left or right outfeed

GLIMEK SD-600 Suction Dough Divider

SD-600

Features

- Weight range: 3-pocket from 150 to 3000 grams, 2/4-pocket 250 to 1700/100 to 700 grams

- Variable speed with frequency converter

- Capacity: 3-pocket from 1500 up to 4500 pieces per hour, 4-pocket from 2000 up to 6000 pieces per hour, 2-pocket from 1000 up to 3000 pieces per hour

- High quality components and choice of material

- Very user friendly 8 inch touch screen for settings and storing recipes

- Stepless adjustable pneumatic system for very gentle handling of different types of dough. Can be adjusted during operation

- Reliable dividing system with very high weight accuracy

- Separate drive on outfeed conveyor

- Smart monitored lubrication systems that give the machine a long life span

- Quick release on outfeed conveyor

- High attention on borh safety and hygienic aspects

- PLC touch screen for meny based navigation

- 100 liter stainless steel hopper as standard

- 225 liter stainless steel hopper (optional)

GLIMEK ICP Intermediate Pocket Prover

ICP

- Capacity of up to 3600 pieces per hour

- Removable plastic covers on both sides

- Belt width of 350 mm

- Made of strong special aluminum profiles

- Drum motors with frequency controlled drive as standard

- Outlet sliding plate – fixed (option)

- Outlet sliding plate – turnable 1500 mm or 2500 mm (option)

- Separate stands (option)

- Cealing suspensions (option)

GLIMEK CR600 CONICAL DOUGH ROUNDER

CR600

- Capacity up to 6000 pieces per hour

- Weight range: 30 -1500 grams (subject to dough characteristics)

- specially designed infeed track catches the dough in a smooth and gentle way, manually adjustable.

- stainless steel frame and cover

- hygenic materials, easy to cleam due to adjustable tracks and stainless steel execution

pictured with outfeed conveyor /support feet

GLIMEK MO881 Industrial Moulder

MO881

Features

- Capacity up to 3600 pcs/hr

- Driven by tension timing belt

- Noiseless and sustainable

- Three adjustable pressure rollers with spring loaded scrapers

- Easy to clean

- Two separate pressure boards

First pressure board is delivered in two widths, 220 or 280 mm foldable, second pressure board 650X1100 mm - Collection tray with two positions

Enables outfeed with or without stop

Capacities

- Up to 3000 pcs/hr

- Weight range 30 up to 1800 grams

- Working width up to 650 mm

GLIMEK Industrial Bread Line

- high capacity

- high dough weight accuracy

- wide weight range

- comprehensive safety features

- stainless steel construction

- touch panel operation

- common e-stop

- flexible and modular design

- seamless product production

GLIMEK MO211 MOULDING EXTENSION – LONG ROLL

MO211

- For delivery with MO881: in stainless steel, assembled on MO881 with common electrical control

- For delivery as stand-alone: In stainless steel with separate electrical control, assembled on height adjustable lower frame in stainless steel, movable (on wheels two of which are lockable)

- Capacity: up to 3600 pieces/hour

- Weight range: 30 – 1800 grams

- motorized pressure board on top-adjustment in height

- Driven by drum motor, noiseless and sustainable

- fixed lower part to achieve couter rotating direction of the dough piece

Bakery Equipment

Bakery Equipment