-for the production of very round and tight dough balls

-handles 1 – 32 ounces

-36″ diameter turntable

-one person operation

-for the production of very round and tight dough balls

-handles 1 – 32 ounces

-36″ diameter turntable

-one person operation

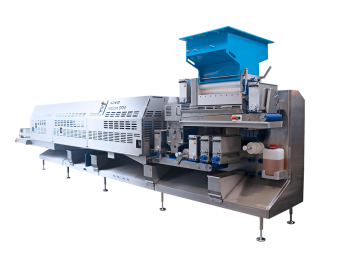

-capacity up to 300 loaves/hour

-handles up to 17.3″ L x 12.2″ width x 6.3″ height loaf size

-available with integrated bag blower

-available in a variety of slice thicknesses (must pick one)

-countertop slicing

-handles up to 17.3″ L x 11.8″ width x 7″ height loaf size

-available in a variety of slice thicknesses (must pick one)

-with turntable

-for the rounding of tight round pizza dough balls

-from 1 – 32oz

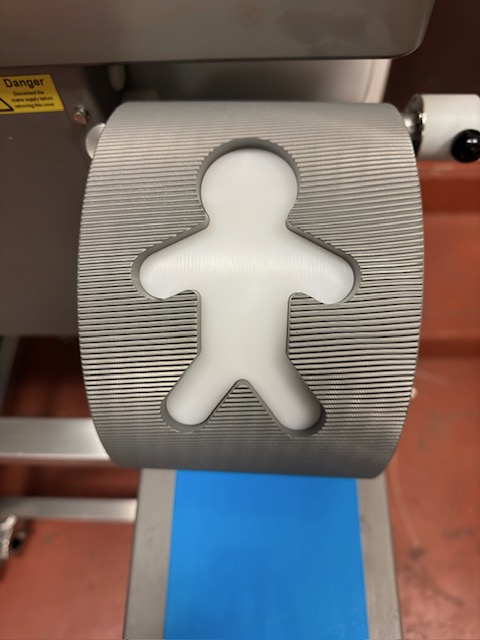

Are you ready for your Christmas cookie production? Contact us today for your Christmas cookie drums to arrive in time for the holiday season!

Model D32

-36 division

We look forward to seeing you at our booth at the Bakery Showcase 2024 at the Toronto Congress Center May 5 -6th. More information on demonstrations and show specials to follow!

Wishing you a joyous and prosperous holiday season and all the Best for 2024!

Dosing action:

-lightly used Mixers (for demonstrations only)

-20 quart capacity

-complete with bowl, hook, whip & beater

Come and visit our booth #228/230 at the Vancouver Bakery Showcase 2023 – at the Vancouver Convention Center!

Register here: Bakery Showcase 2023 – Login – CONEXSYS Registration (myconexsys.com)

Model TallRound

combination of cylinder and cone to provide an optimal rounding process

Year of mfg: 2011

Voltage: 575 volts/3 ph/60 Hz (changeable upon request)

Featuring this week information on the operation and cleaning for the GLIMEK Dough Divider! Click on the below video link for further info!

(2) How to adjust settings and clean the Glimek Dough Divider – YouTube

We would be pleased to meet you at IBIE (Sept 18 – 21) at any of our vendor booths – contact us at 1-888-925-6644 for more information!

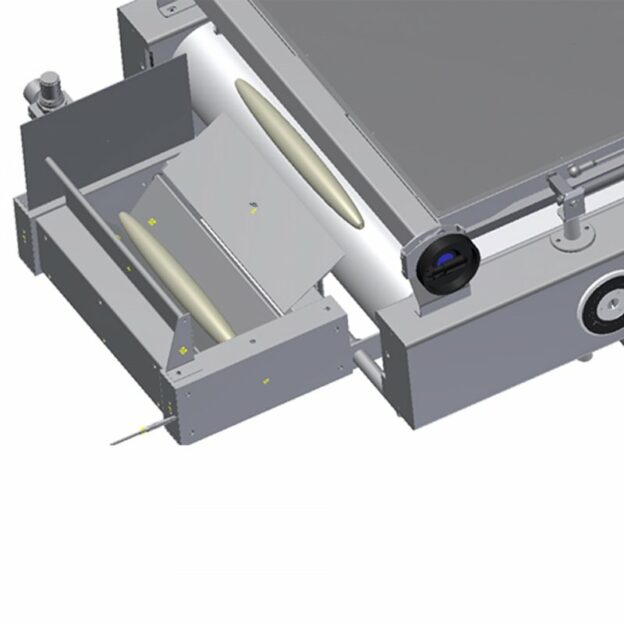

-2 pair of adjustable pressure rollers with spring loaded scrapers

-foldable 650mm wide pressure board

We look forward to welcoming you at our Booth #206 at the Toronto Bakery Showcase on April 10-11th at the Toronto Congress Center!

Wishing you and your loved ones a Happy Holiday Season!

Our holiday hours are:

Have a safe and Merry Christmas!

-wide variety of bread pans available in either a 4-strap or 5-strap

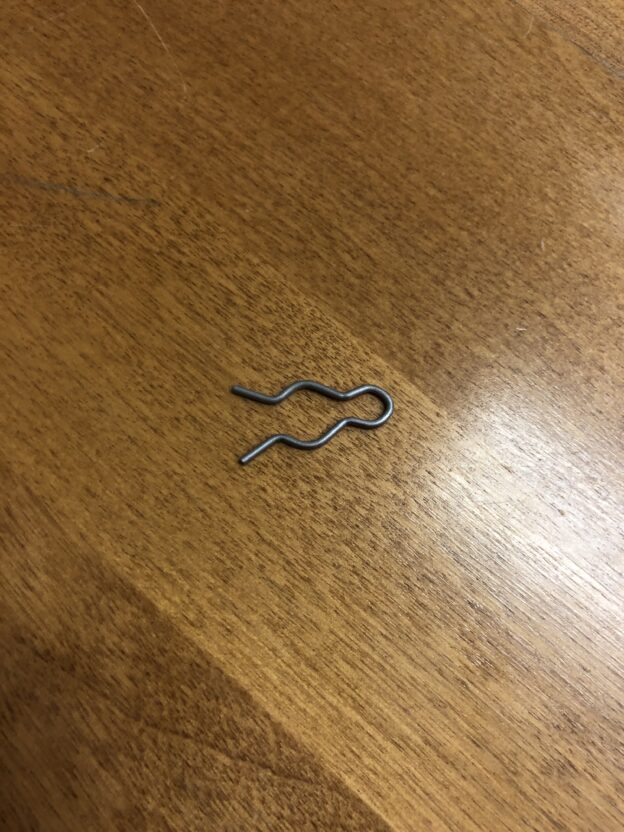

Stud, Swing 0797-0057-2

Eccentric Pin 0777-0034

Top Link 0711-0002

Connecting Rod Assembly 0797-0071-4

Hairpin Stud Pin 5835-7705

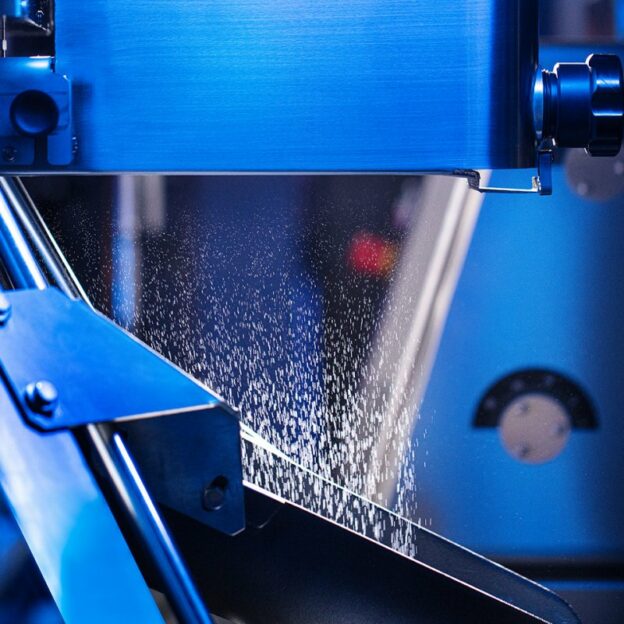

Depending on customer requirement Glimek has different solutions for flour dusting all through the baking process. Compatible with Glimek Bread Lines.

The Glimek Semolina Flour Coating System (COS) can be integrated in Glimek bread lines when there is a need for coating of flour around the dough piece. The machine has an internal infeed conveyor, where the initial coating of the dough pieces takes place. The conveyor feeds the dough pieces into the perforated plastic tube who rotates them while coating them with granules. The tube’s angle and rotation causes the dough pieces to be fed forward.

Excess granules fall through the tube and screen into the collection box. From there, the vacuum unit returns the granules to the distribution unit.

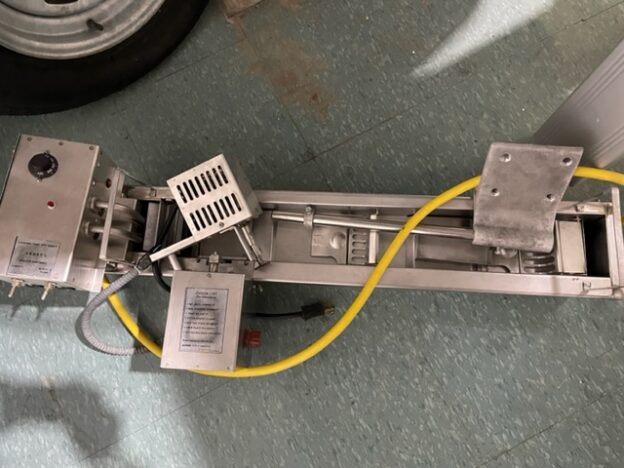

The DU400 is a decorating unit intended for the application of oats or different types of seeds, such as sesame and poppy to dough pieces. DU400 cannot be used to apply flour. The unit is normally placed between the pressure boards of the Glimek Dough Moulder MO881.

This seeding applicator is equipped with a rotating roller made of approved food grade plastic, which has indentations. The roller runs towards a brush board whereby it releases seeds onto the belt beneath, which carries the dough pieces. A photocell senses the dough pieces passing, so an individual application occurs for each dough piece. On the front of the electric cabinet are time relays for start delay, as well as the run time. It can be set for intermittent operation or for the seeding applicator to run continuously.

When the seeding applicator is mounted between the pressure board, on the Glimek Moulder MO881, the seeds are pressed towards the dough piece under the final pressure board, which means that the seeds will be pressed into the surface of the dough piece.

Glimek Dough Piece Separator – DPS unit separates dough pieces in two rows (normally after the conical rounders) to be able to handle intermediate proofing and moulding for higher capacities.

Glimek offer customer adapted conveyor systems. We can design different types of conveyor systems for transportation of dough pieces, baked bread or tin sets. The design is determined together with the customer according to customer specification.

The Glimek depositing unit is fitted with two flaps to catch the dough pieces from the moulder. A photocell tells the flaps to open when the space beneath is ready. This ensures that the dough rolls are released at the correct time and in the correct position.

Glimek V-Belt Charging System for automatic charging of dough pieces on swing tray proofer or belt proofer.

The Glimek stainless steel Retracting Charger for the automatic setting of dough pieces coming from the make-up line to the proofer conveyor belt, baking trays or similar.

The BC250 Belt Conveyor, transports the dough from the Dough Piece Seperator to the Intermediate Pocket Proofer. Easy to move and clean.

One of the most flexible pocket proofers on the market. For 6, 8, 10 or 12 pockets. Modulated for easy adaption in height and depth, available in standard models from 132 up to 1128 effective pockets. Solid construction in stainless steel materials.

A ventilation and fire suppression hood is usually required for indoor locations.

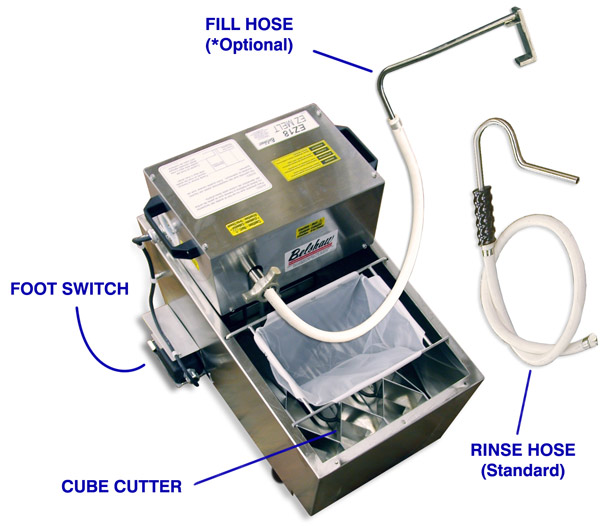

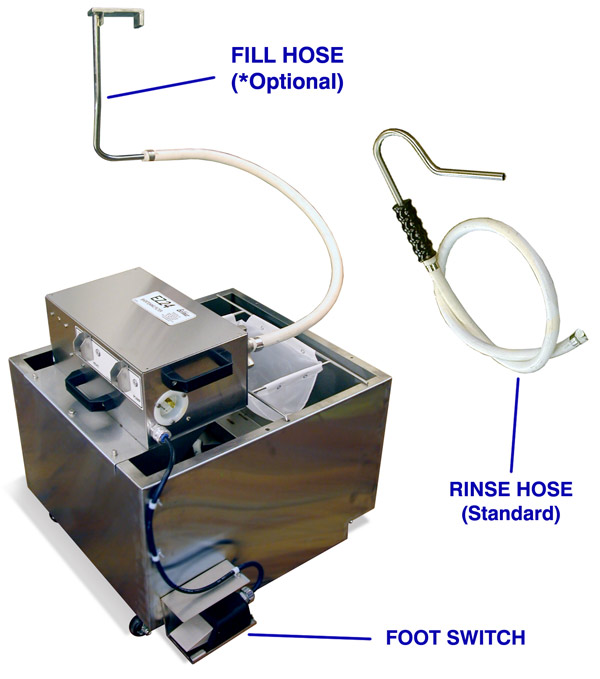

The EZMelt18 is a recycling filter that heats shortening in the tank, with these benefits:

Standard features

The EZMelt24 is a recycling filter that heats shortening in the tank, with the following benefits:

Standard features

Compatible with 616B, Cut-N-Fry, Donut Robot Mark II, Mark II GP, Mark II Gas, Mark II GP Gas, Mark V, Mark V GP Fryers.

The Filter-Flo is a dependable heavy duty siphon that extracts and filters shortening from fryers, in situations where there is no room for a built-in drain, or if your fryer has no built-in drain. A squeeze of the large bulb starts the flow which can empty a Mark II in a few minutes. A reusable cloth filter cleans as the liquid passes through. Note: the Filter-Flo requires a customer-supplied leakproof container for filtered shortening to pour into. Filter-Flo is not needed if you already have a shortening filter such as SF or EZMelt

https://www.harvestbakeryequipment.com/cms/wp-content/uploads/2021/04/KLR.mov

View our latest video of a Silo System Installation.

OLIVER products is launching this spring their new 797 Gravity Feed slicer. Complete with Proguard safety feature!

7/16″ D x 3-1/2″ Assembly

Presenting the compact N Series for the foodie that enjoys baking perfection.

The N Series is a bench sized combined deck and pizza oven with the same high baking quality as a large oven. Switch from stone baked pizzas and bread to pastries in a moment. Equipped with a high quality heating and steam system with provides amazing results of the baked product. Easy to clean and has a smart heat control which is very easy to handle.

Click below for more details!

Wishing you and your families a Merry Christmas and a safe and happy New Year!

Versatile that you can grind fresh or dried bread for crumbs, nuts, cakes, biscuits etc. Variety of screens and wide range of throughput – call today for further information.

#006

#087

Sichelmesser fuer Brotschneidemaschine Roesen & Robbert

15 ON, 4″ DIAMETER, 18 X 26 FRAME REGLAZED – IN GREAT SHAPE – 193 PIECES

Together we are facing a global COVID-19 pandemic that is affecting our families, communities, businesses and our way of life.

We will continue to operate on regular working hours during this situation. We are taking all necessary precautions to ensure the continued safety of our customers and employees while offering all our products and services.

During this time we are encouraging higher use email and phone orders along with offering shipping options as alternatives. Our service department is completing emergency repair only at this time.

Updates will be provided if any changes occur in the future. Stay safe and implement all prevention procedures when possible.

Thank you

Conrad, Marika & the HARVEST TEAM

We look forward to welcoming you to our booth at Toronto Bakery Showcase 2020 on April 26 & 27. We will be at booth #503 and will have demonstrations running throughout the show!

As part of our ongoing skills training and upgrades, we are pleased to have some of staff participate at the GLIMEK Technical training seminar held at the Baking Innovation Center in Plano Texas!

The KOENIG Rex is the new “workhorse” in this plant producing DONUTS! Client is extremely pleased with the production and consistency of his new KOENIG —

MANUAL Dough Divider

Machine for rounding loaves, balls and short breads with weight from 76 grams up to 4000 grams (rounding).

A very flexible and high capacity cone rounder for all kinds of bakeries and is suitable for most types of dough. Two individually adjustable rounding sections processes the dough for ultimate rounding and optimized results.

Our client is pleased with the results in using his new Hinds-Bock depositor for his gluten free product line. Check out the video!IMG_9482

The dough sheeting line for large and fine-pore doughs in Easy Clean Design

Performance features:

Another SVEBA-DAHLEN deck oven supplied to a happy baker in Calgary AB —

All these units are already sold to happy Bakers whose customers will experience an endless variety of rolls!