All these units are already sold to happy Bakers whose customers will experience an endless variety of rolls!

All these units are already sold to happy Bakers whose customers will experience an endless variety of rolls!

Recently installed SVEBA-DAHLEN installation featuring the S400 Oven with underbuilt SJ400 Proofer – customer excited to start baking soon!

Our SVEBA-DAHLEN deck oven comes in all different configurations – check out this one!

Latest installation –customer is thrilled with the baking results with their SVEBA-DAHLEN ovens!

Model Gemma

-2 motors, 2 speed each

-choice of two panels (manual controls or user panel)

-temperature probe

-efficient hydraulic system

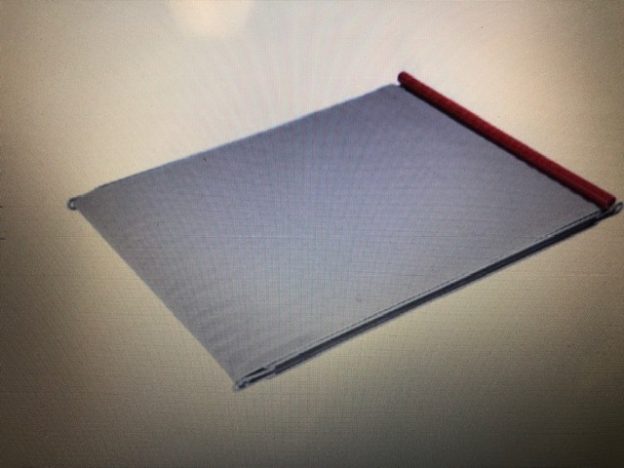

overall dimensions 60 cm x 80cm

-for storing shaped doughs during fermentation and for transferring doughs onto the surfaces of ovens or onto oven insertion mechanisms

-stainless steel structure

-linen material

Yevgeniy

Service TechnicianP: 905.568.2002

F: 905.568.2024

[email protected]

Most recent installation of SVEBA-DAHLEN Deck Ovens!

Complete with stone inserts, steam and D1+ panels for finesse control over sensitive products!

Now offering the SVEBA-DAHLEN Deck oven with

three different panel options to suit bakers needs

and economics!

Click for more details: deck_oven_panels_0

Don’t miss the upcoming Bakery Showcase April 29 & 30th 2018 – We are pleased to welcome you to our booth #141!

Show hours at 11.00 am – 5.00 pm both days at the Toronto International Center Hall 5

Just completed installing a deep hearth Deck Oven installation together with Easy loader system.

We are excited to bring the latest in technology to our booth #507 at the Bakery Congress in Vancouver April 23 – 24th 2017!

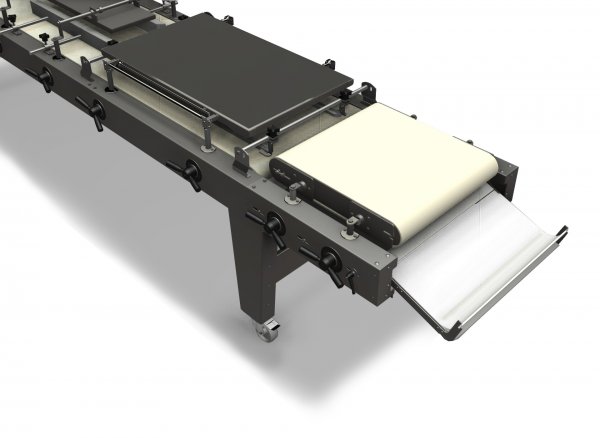

Jac Bread Slicer blades 13mm x 0.05 standard for 450 models

pictured with outfeed conveyor /support feet

The modular roll line with a capacity of 33 strokes/min in Easy Clean Design

The Combiline plus EC is a modular line which fits to the requirements of your bakery. By means of your special conditions, market requirements and investment spending, you define the configuration of the line. And Koenig builds it in the way you need it. In case you will need an additional level of automation later on, the line can be easily expanded without major engineering work and with minimal disruption to your production. The Easy Clean Design offers easier cleaning, maintenance and access to all modules.

Performance features:

The Industry Rex Compact AW offers an ideal balance between weight accuracy and gentle dough processing. The variable separation of the dividing pistons and rows of this dough dividing and rounding machine allows to cover a weight range from 25 to 350g in only one machine – and nevertheless in compact design. To achieve this, the proven „Multi“ principle with easily exchangeable dividing ledges has been applied to this machine.

Performance features:

Cleaning and Maintenance:

Uniquely high performance of 100 strokes/min for a great variety of rolls

Performance features:

Compact countertop dough moulder delivers on quality, simplicity, and labor savings!

The Bloemhof Bread and Roll Moulder Model 860L is a simple, versatile bakery workhorse. Easily and with single person efficiency mould rolls and breads ranging from 1/2 ounce to 7 lbs.

Key Features:

The Bloemhof Simplex Sheeter/Moulder combines sheeting dough and moulding dough in one unit!

Key Features

The high-performance dividing and rounding machine T-Rex AW achieves with specially designed rounding ledges the high output of 100 strokes/min. The dough pieces are thereby gently and virtually smooth rounded.

Performance features: